Sewing machine technology and tips

Sam Sloan, Ron Russell and Rich Ludwig in the Sloan Machinery booth at the MFA National Convention at Cape Coral, Fla., earlier this year.

At Hood Canvas, as with all fabrication shops, the single-needle walking-foot sewing machine is the backbone of our business. Every shop has its favorite brand of machine and has achieved a level of comfort in everyday use. We have had many different brands of machines over the years and they all had one thing in common: They all were of the “turn the flywheel by hand with noisy clutch motors and no automation” variety. Upgrades were large bobbins and being able to reverse the action. Sam Sloan of Sloan Machinery and Ron Russell of Groz-Beckert Needles have helped us and our students understand the advantages of sewing-machine and needle technologies.

This is one of our three Juki LU-1508N-7 sewing machines, each equipped with AB321A Efka needle position servo motors and Groz-Beckert SAN (special application needle) 5 needles. All new Juki’s have a rectangular feed of the walking foot instead of the elliptical feed most machines have. This enables plies of fabric to sew uniformly and smoother. The Efka needle position servo motor can be added to any existing machine. It makes precise control possible with a silky smooth German motor. We turn the speed way down for our students, which makes learning to sew a snap. It never makes a sound until you step on the treadle and always stops with the needle down. Heel back on the treadle and the needle raises and releases the thread. It is a pleasure not to have to reach for the flywheel (though you can if you want to). Tap the treadle once, and the machine does one stitch, needle down. Repeat one stitch at a time. This is a real time saver, especially for cushions and upholstery.

This is a photo of Sloan Machinery. We make field trips here with our students, and Sam Sloan frequently serves pizza and soda. Sam is always willing to help our students and the MFA with any and all sewing issues. The new Juki LU-2810N-7 models should be in soon, and they will feature direct-drive, 6 inches more clearance from the needle to the machine arm and auto everything. It is hard to part with that old comfortable Consew, but, these new machines, while not for everybody, we would like one.

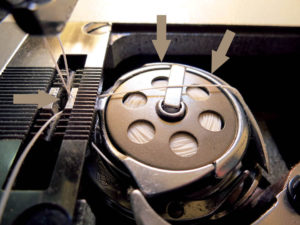

When sewing with any machine and there is a sound different from the usual chug, chug—stop! The arrow in the photo points to a problem with the thread path. Always look for the simple solution first. Check the thread path to be sure it is clear, and then change the needle. According to Ron at Groz-Beckert, changing the needle is a very inexpensive fix that cures a multitude of problems.

The arrow points to the groove in the bobbin case into which we place a drop of oil every other bobbin change. This is the fastest-moving part in the machine, and oiling here will increase the life of the hook. We also place a drop of oil on our finger and rub the needle bar at the same time to increase the life of the bar. This is in addition to regular routine machine oiling.

Here are some tools for machine upkeep. The top is an abrasive cord for smoothing out feed dog holes. The needle goes through this hole in the base of the machine. The bottom is a honing stone for removing burrs on the lead up to the hook and the hook itself. Use an air compressor blow gun frequently to remove lint build up around the hook area; such lint is an abrasive that will shorten the life of the hook. Also, be sure to use WD-40 or 3M adhesive remover to remove adhesive buildup in the hook area.

This is a trick that ace sewing-machine mechanic Freddie from Sloan Machinery taught us. Pull out the bottom thread and at the same time move it in a circle around the feed dog opening following the arrow. If there is a burr in that area, the thread will break and you know where to look.

All PTFE thread tends to be abrasive to a hook. Every shop has its favorite brand. We are partial to Solarfix thread as we tend to have fewer issues and greater sew ability with that particular brand of PTFE thread. Regardless of brand, all PTFE thread tends to wear the hook at the location of the top two arrows in the photo. The photo shows the thread loop forming around the bobbin case and moving (in a clockwise direction) over the area of the two arrows. If you have thread breakage issues, run the edge of your fingernail along the arrow edge to feel for burrs. If any are found, smooth lightly with the honing stone—from left to right only. If burrs are on the outside edge of the hook point you can do the same, very lightly, clockwise left to right only. Always off the hook, never into. The left arrow points to the feed dog hole. If there is a burr, remove the feed dog from the machine and place in a vise. Use the abrasive cord running through the hole to smooth out and reinstall the feed dog. With all PTFE thread, you must use considerably more top tension than a bonded polyester thread. Remember: Thread tension is the opposite of what you would think. The underside of the fabric is controlled by top tension on the machine head. The top side of the fabric is controlled by a tension screw in the bobbin case.

This is a photo of the Groz-Beckert SAN 5 needle we use most often at Hood Canvas. The figure in the upper left 135 X 17 is the only needle system that will work on our Juki LU-1508N machines. The last two digits in the upper right are the size of the needle. In this case it is 21, but we use a smaller or larger size depending on the material being sewn and thread size. To the right, below the red dot, is the point style, which, in our case, is an RG.

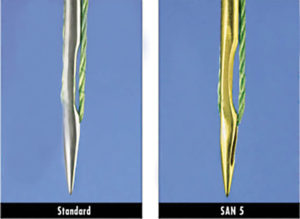

This is the Groz-Beckert SAN 5 needle. It has a Titanium Nitride finish for maximum life of the needle point. Ron Russell from Groz-Beckert explains that the SAN 5 needle has a deep scarf and a special eye design. Even with a poorly formed loop, these features guarantee a greater space between the thread and the needle, assuring loop pick up by the hook. This leads to a higher security during the loop pick up and the highest reduction of skipped stitches and thread breakage. We love the SAN 5 needle as we have fewer issues than with any other needle.

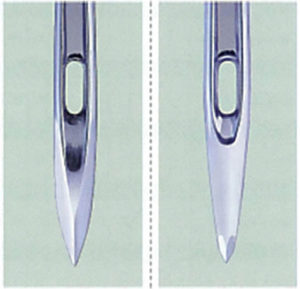

Two other point styles. We like the RG point style as it tends to wear better and have less material damage.

On the right in the photo is a SAN 5 needle with an SD point. It has a small triangular cutting tip that we use for sewing lighter gauges of polycarbonate. We like this point as we get less residue from making the hole on the backside of our sewn piece. The finished enclosure panel looks better on the backside because the cut piece of polycarbonate drops into the tray under the machine. On the left is the D/TRI point that we use for sewing heavier polycarbonates.

Mark Hood, MFC, and his wife, Deb, own and operate Hood Marine Canvas and Hood Marine Canvas Training Workshops in Merrimac, Mass. For more information and to purchase the large binder seen in these articles, visit www.hoodcanvas.com, email mark@hoodcanvas.com or visit the Facebook page.

TEXTILES.ORG

TEXTILES.ORG