Window Treatment Trends

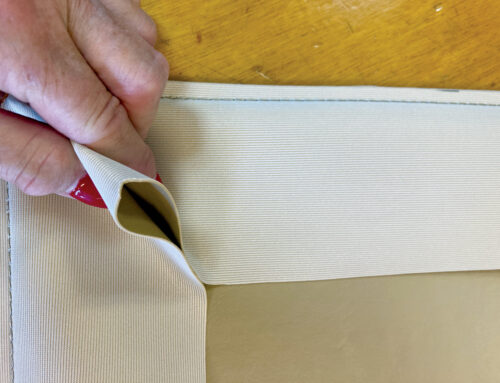

New 1-inch cordless Wood Tension System on a 650 Sea Ray in American Walnut color.

Photo Credit: Poseidon Window Treatments

Interest in window coverings for marine applications has experienced a rebirth of sorts and more consumers, fabricators and designers are using innovative window treatment designs.

When Krisha Plauché, owner of Onboard Interiors in Marblehead, Mass., is fabricating drapery for a stateroom, she often uses blackout applications, but Plauché has found that lining drapery with a Sunbrella® fabric can also work nicely.

Chris Costa, owner of Costa Marine Canvas in Egg Harbor City, N.J., says that mesh sun screens are becoming very common today.

“We do a lot of sun screens on enclosed flybridge models, especially the front windows where they can’t install permanent blinds,” Costa says. “Sun protection, electronics protection and privacy are the main goals. Stamoid Soltis 86 is our preferred fabric because it allows 14 percent of light to pass through.” Serge Ferrari Stamoid Soltis 86 guards against UV and wind, allowing transparency while preserving privacy.

Alex Garcia at Poseidon Window Treatments in Dania Beach, Fla., says many of the trends involving window treatments have been going toward cordless and motorized operating systems. For example, Poseidon’s new cordless 1-inch Harbour Wood blinds work on a tension system rather than the standard pull cord.

“Our clients love it because while their boat is in motion, they do not have cords swinging about whether the blinds are up or down,” Garcia says.

Coral Honeycomb blinds from Poseidon Window Treatments in Steel Weave color on a Formula 430.

Photo Credit: Formula Boats

Honeycomb fabric is Poseidon’s most popular window treatment fabric. Not only is it a great material for specialty shapes due to its flexibility, but it also comes in a multitude of both light-filtering and blackout colors and patterns.

“Another great feature of this type of fabric is its energy efficiency,” Garcia says. “This is especially true with the blackout versions due to their foil lining inside. And as we all know, life on the water can be both blistering hot or numbingly cold.”

With the advent of 3-D printing, Poseidon has been able to engineer new ideas and components more efficiently and at a lower cost. What was almost impossible to do just a few years ago at a reasonable cost, Poseidon can now do in half the time and at a fraction of the cost before a new design goes into production.

“That lower cost we can pass on to our clients now,” Garcia says. “What this means for the future is that anything is possible when it comes to design and functionality. In the past, many boat and yacht owners had no choice when it came to specific window shapes, whereas in the near future, they will have choices like never before.”

Maura Keller is a freelance writer from Plymouth, Minn.

TEXTILES.ORG

TEXTILES.ORG