Selecting the best fabric

Photos 1 and 2: Designer and private label textiles, such as this Ralph Lauren anchor pattern, can cost $100 or more per yard. Using a matching tone in a solid Sunbrella® fabric on the zipper bands and bottom lining can help keep a project within budget.

Thank goodness for Dr. Google! When sourcing textile options for projects, fabricators can simply type in “marine fabric” and up pops a plethora of vendors and nautical-themed images. You’ll find individual maritime insignias that correspond to each of the 26 letters of the alphabet as well as graphic illustrations for almost every kind of nautical hardware—from anchors to navigation wheels. Also in abundance are fish patterns, playful sea horses and giant photorealistic renderings of marlin, swordfish and many other images that can be used on accent pillows, custom cabin quilts and pillow shams on larger vessels.

Budget for success

The initial discovery meeting with your client lays the groundwork for a successful project. Obviously, you will discuss the scope of the project, color palette, etc. But most importantly, you need to understand the client’s budget. Clients often avoid giving you a firm number, but moving forward without a sense of the budget can be a tremendous waste of time for both you and the client.

Photos 3, 4 and 5: Images such as flags and the nautical alphabet add dramatic flair to interior decor.

As you narrow your offerings down to a few key textiles that fall within your client’s budget, keep in mind that you can introduce a dramatic fabric as a focal point with as little as one yard of material. Using dramatic textiles makes a strong impression and helps ensure your position as a preferred fabricator. Check with your supplier about minimum quantity requirements, yardage availability and lead times.

It’s important to have a realistic sense of how much yardage is required for the items to be fabricated and to charge accordingly. For instance, an L-shaped sofa can easily require up to 14 yards of material. If your cost for material is $25 per yard plus a 50 percent markup, this translates to $525 for the fabric alone. Cost has to be taken into consideration if the project requires foam upgrades. Additionally, calculate the time and cost of removing the original material, fabrication of the new covers and the installation. And keep in mind that projects incorporating fabrics with patterns will require additional yardage.

At Sand Sea and Air, we use spreadsheets to calculate the material costs for each project, the fabrication steps necessary and the time each step requires. After we complete a project, we go back to analyze and record any changes that affect the final “true” costs and profit for each project. This system ensures we’re not losing money on a project and helps us tweak our budgets moving forward.

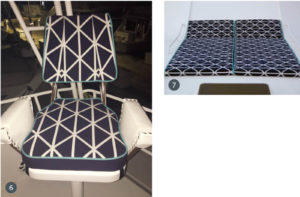

Photos 6 and 7: This pattern required us to balance horizontal and vertical repeats as well as a hinge fold in the bow cushions to accommodate the incline of the vessel. The final seams on the pilot and copilot seats reflect a harmonious transition, yet it was extremely challenging to fabricate the high/low back cushion in harmony with the seat cushions.

Tricky cabin tricks

Creating bedding for fitted mattress covers and cabin quilts presents specific challenges. Mattresses often have oval curves rather than a traditional rectangular shape, and you many need to work around framing that holds mattresses in place. Also, a master cabin bed is generally 60 inches wide, yet material is often available in 54-inch widths. To ensure you have sufficient material, it’s important to calculate and construct the additional sections on both sides of the center yardage with consideration to the pattern repeat on the top panels. I prefer to use the full 54-inch-width as the center and then use narrow bands of 4 to 6 inches of fabric on either side.

Additionally, side mattress bands can be as high as 10 inches, which means a good portion of the side bands will be visible. You will need to maneuver the fabric pattern repeat to get the most attractive part of the 54-inch width in the band front, with seams joining as needed toward the sides.

We recently fabricated fitted mattress covers for a queen-size bed in a Ralph Lauren anchor pattern. The material had anchors twisting left and right, some in opposite directions, while others were in the same direction along adjoining rows. Since this fabric was expensive, we used a matching tone in a solid Sunbrella® fabric on the zipper bands and bottom lining, as they would not be visible once the mattress was onboard. This helped keep us within budget and ensured a successful project.

Photos 8 and 9: It’s important to calculate the waste factor on side-by-side cushions when the visual pattern must remain harmonious. It can be as much as 14 inches, as was the case in the Kravet® Turquoise Flamestitch pattern with a 17-inch height repeat. Fortunately, that was exactly the height needed for the upper back cushions. We darted the excess fabric in the center of the curved corner cushion so the sides maintained the continuous visual repeat of the pattern. We also manipulated the fabric along the sides and back of the bow headrests to continue the dramatic pattern seen on the front of the cushion.

As you fabricate the details of your projects, imagine each one as a winning entry in the Marine Fabrication Excellence Awards. Careful planning and execution will create a complex masterpiece that embodies more than form, fit and function for your customer; it will provide the personal satisfaction of a job well done.

Terri Madden owns Sand Sea & Air Interiors Inc.in San Juan, Puerto Rico. www.sandseaair.com.

TEXTILES.ORG

TEXTILES.ORG