Tricky client design challenges

For most fabricators, long-term success doesn’t come from the easy jobs, but from the challenging projects. Using two case studies, I’ll present a few design challenges I’ve encountered in the hope that my experiences will help you work more smoothly with clients and shorten your learning curve.

Case study 1: Agree on the design vision 70-foot Hatteras

Having been a marine fabricator for nearly 40 years and the owner of Banner Canvas in Ham Lake, Minn., for 24 years, I’ve acquired a broad array of interior and exterior product sample books. I usually feel confident that bringing a good selection of fabric books to the initial client meeting will ensure that clients find something they like among the options I’m presenting.

For this project, I was excited to work with the clients (a husband and wife) because they wanted to give their boat a completely new look. As I laid out some of my books, I quickly discovered that she had one style and he had another, a fairly common scenario. She then asked me if I could get a particular color and pattern that she had found on Wayfair (Photo 1).

Wherefore Wayfair

How, I wondered, looking at all the sample books I’d brought along, could I compete with Wayfair, an online home furnishings company with an enormous product line? She asked if the pillows we were discussing were the Sunbrella® brand and did I carry that line?

I assured her I did and brought out all my Sunbrella sample books. Unfortunately, her requested pattern was not to be found in any of them! So, we ended a two-hour client meeting with the clients not locating what they were looking for in any of my sample books. I suggested we do some further searching to find something they both liked.

I directed them to the Sunbrella website to look at patterns that were not available in my books. In the meantime, I started searching for the Wayfair pattern and color. After a time-consuming search, I realized that what they wanted did not exist.

My first thought was: Did this pattern once exist, and it was at the end of a roll and sold off to Wayfair to construct pillows for the home goods market? No. I eventually learned that Sunbrella manufactures patterns specifically for other companies, such as Wayfair and SilverState fabrics, and the companies have exclusive rights to those products. This means these patterns are not available in the open Sunbrella line but are offered only to the contracted companies.

A balancing act

The second client meeting took place at their home, which gave me a chance to see their style of decorating. This helped a great deal because people often carry over their home decorating style to their boat. I brought along turquoise cushions as an example of the size and color they requested (Photo 2). One of the lessons I’ve learned is that despite clients telling you they are looking for “a change,” they often gravitate to the same color and pattern they’ve used before. You might spend a lot of time exploring different options only to end up with a familiar color and pattern.

This is why it helps to have a diverse portfolio of suppliers—it allows you to steer clients to a design line best suited to their tastes. In this situation, I chose Sattler’s Outdura® line, as it was closer to their home design choices.

The tricky balance here is keeping the focus on their boat while also considering their home design. It’s important to understand the components of a fabric appropriate for a home that may not be suitable for a boat. Helping your clients understand this and presenting ideas about the aspects of their home design that will work well on a boat is the key to finding a design vision that everyone can agree on.

Case study #2: Provide workable options 53-foot Bluewater

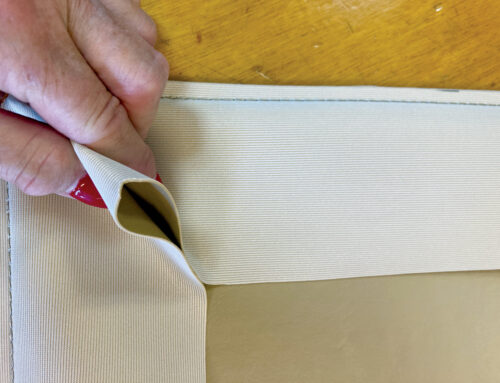

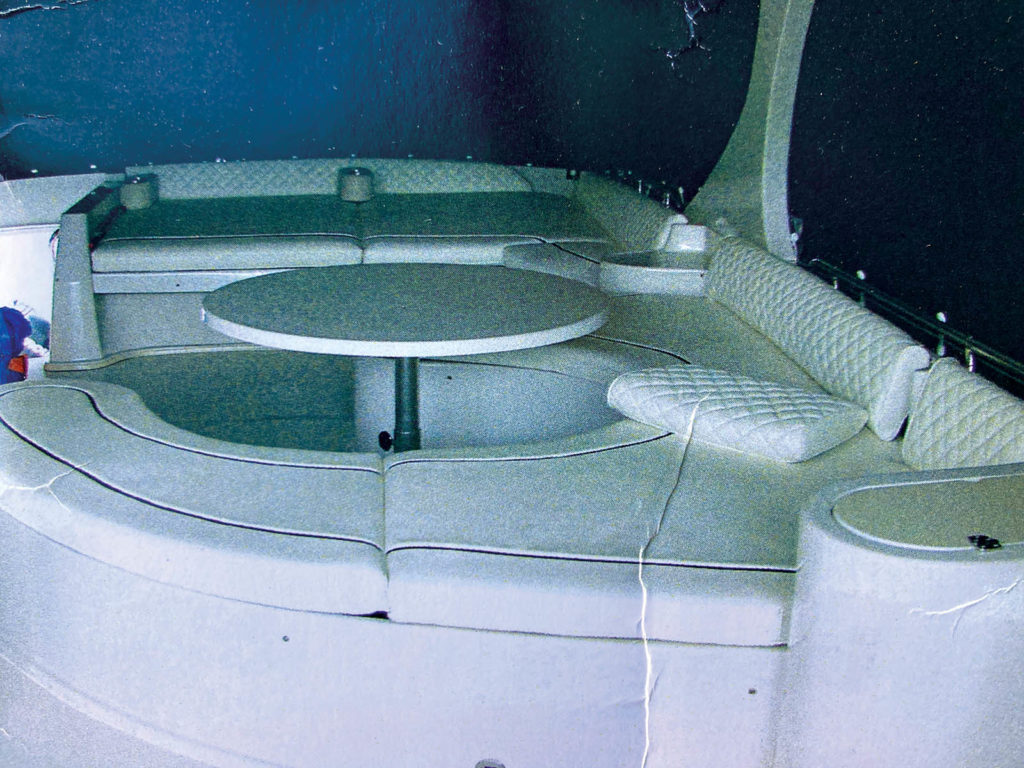

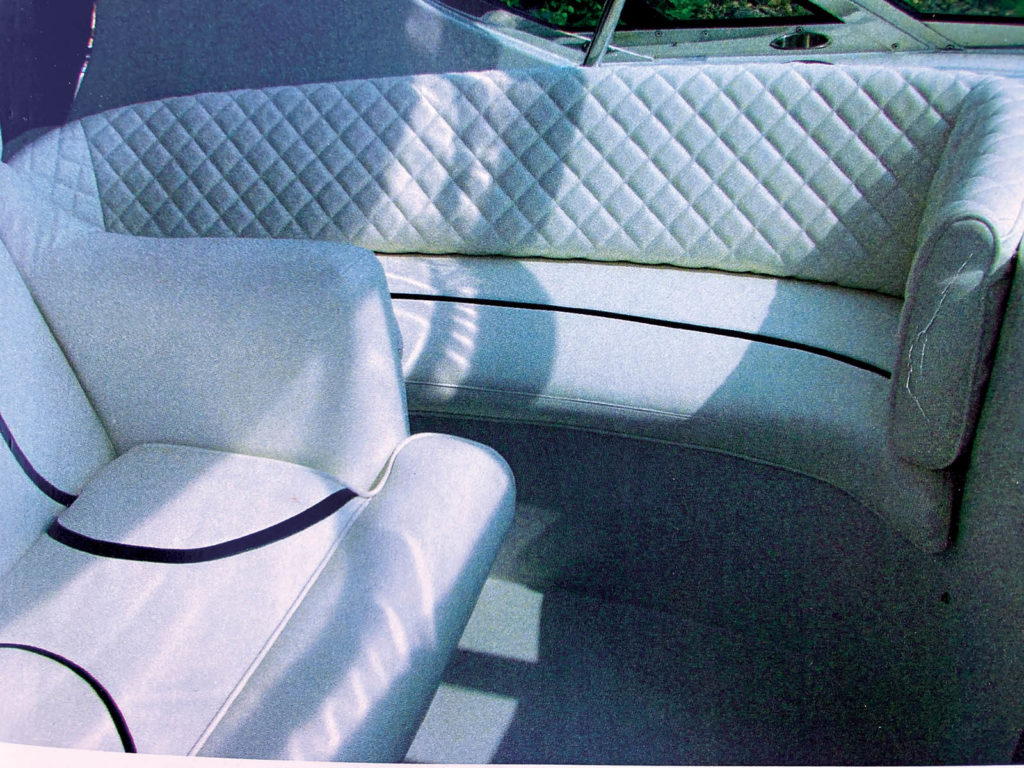

The clients of this project invited me to meet them on their boat. The initial problem was evident in the way the sun hit 19 all-white cushions on the upper deck. The clients wanted to add a black stripe to the design to break up the monolithic appearance, give the cushions the illusion of sections and help reduce the glare (Photo 3). They also wanted to incorporate a quilted diamond pattern into the design. I advised them to do the quilting on the backs only and use the black stripes in the cushion bottoms. In this case the quilting was all done by hand (Photo 4).

Challenges emerge

The initial job went fine, but then the project expanded, as many do, to the interior of the boat.

She wanted a Tommy Bahama theme in the main stateroom, and she found little she liked in the Sunbrella open line. She requested a shower curtain in the head, drapes in the master stateroom and a new headboard. Since I don’t fabricate those items and they spent time at their winter home in West Palm Beach, Fla., I suggested she stop by Canvas Designers Inc., in Riviera Beach, Fla., a marine shop that could help source the drapes and shower curtain.

Collaboration is a win-win

Canvas Designer’s showroom had an abundance of fabric selections on display, and she found several colors in a line from SilverState fabrics (Photo 5). The shop was able to order the drapes, headboard and shower curtain, and I did the installation here in Minnesota.

When the clients returned to Minnesota in the spring, she was able to select fabric for a duvet cover and dining room chair re-cover among the samples I had ordered (Photo 6). Working with Canvas Designers expanded my ability to service these clients and offer them a professional job. It was a win-win for everyone.

One other common collaboration that requires deft handling is with clients who bring along their own designer. Often this designer will have a background in home interiors but may not be knowledgeable about boat fabrics. Whenever possible, I’ll work with the designer to meet the objectives of the clients, while carefully explaining why a chosen fabric is unsuitable for a boat. It can be challenging to find the right balance for all parties but that’s part of the job of being a successful fabricator.

Lessons learned

- Don’t waste time searching for something that doesn’t exist.

- Narrow down client design choices through intentional discussions.

- Observe interactions between clients to better understand power dynamics.

- Steer clients to feasible design options as quickly as possible.

- Have multiple product lines to offer and consider teaming up with a larger marine shop to offer the widest sample inventory to clients.

- Reach out to suppliers and distributors directly to help solve inventory challenges.

Probably the biggest lesson I have learned over the years is the value of industry networking. I can’t emphasize enough the importance of being involved with MFA fabrication forums, national conferences and regional workshops. Developing the ability to make strong connections with clients, other fabricators and suppliers is really the key to business success.

Faith Roberts, MFC, IFM, is the owner of Banner Canvas, a 4,000-square-foot shop in Ham Lake, Minn. She travels throughout the U.S. working on special-project boats. Roberts holds a degree in apparel design.

TEXTILES.ORG

TEXTILES.ORG