Benefits of project boards for custom projects

by Terri Madden

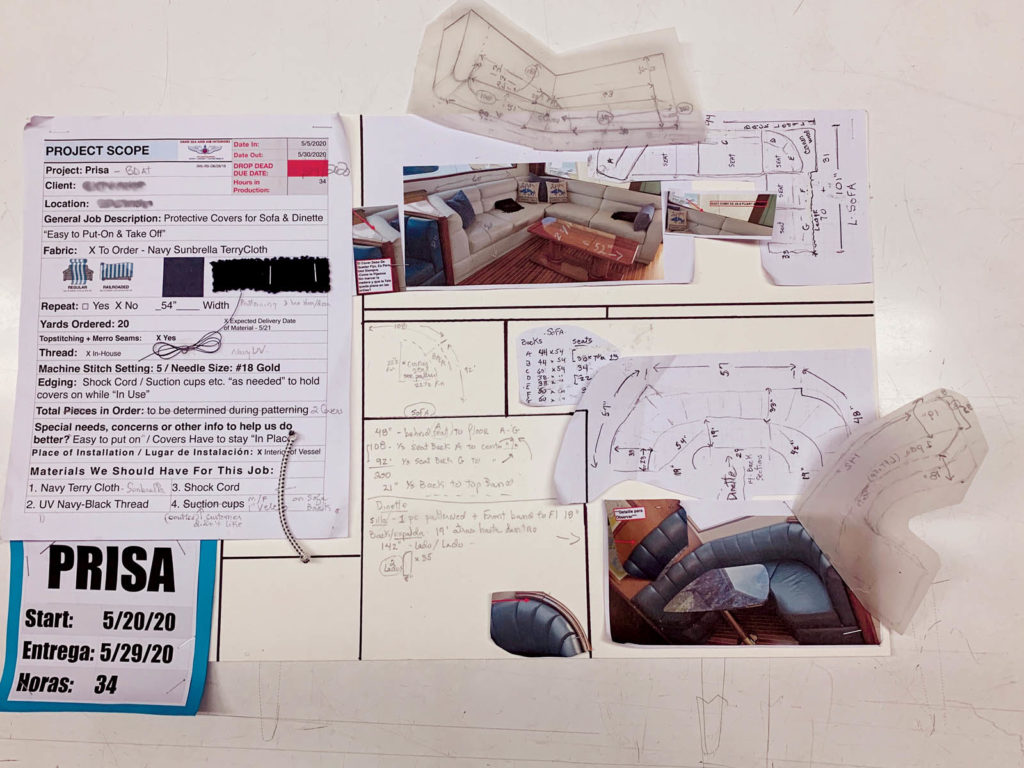

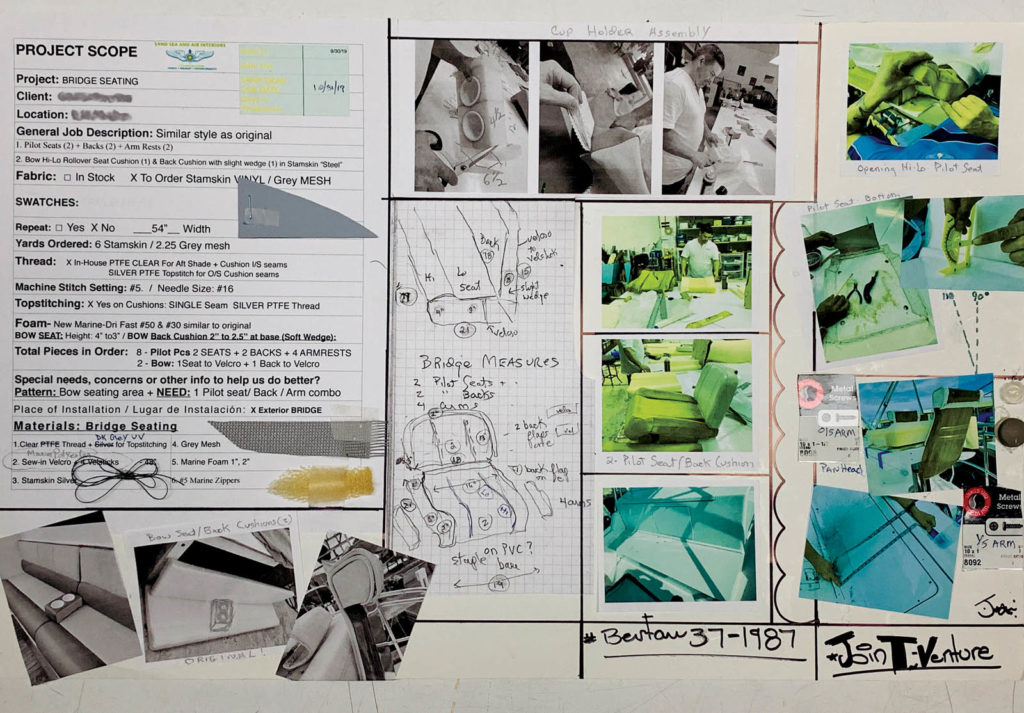

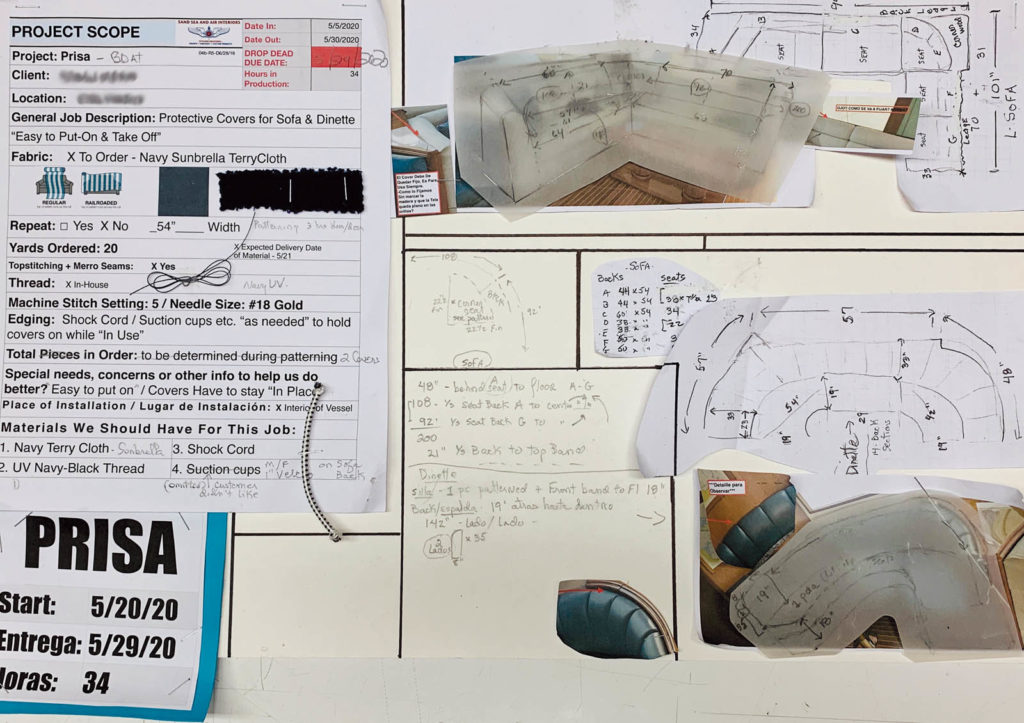

The familiar adage, “A picture is worth a thousand words,” is especially apt when it comes to a project board, a visual summary of all of a project’s components. A project board confirms that you have understood your customer’s requests, and it helps your staff understand and correctly fabricate the details for the planned project. Having these graphic and text references located in one place helps ensure your company will deliver a timely and profitable product.

Sand Sea and Air Interiors is a family business, and my daughter Alayna is involved in everything from customer sales to ensuring we are profitable. A few years back she initiated the concept of a project board for a large project, and truthfully, I was resistant to the idea. We were already working long days, and I looked at the planning and execution of the project board as one more task that would require time versus just getting the job started. But I now see that having a project board provides far more benefits than I initially imagined. Beyond timely completion and increased profitability, the board generates excitement among our team and helps team members envision the scope of the project and their roles in completing it.

What to include

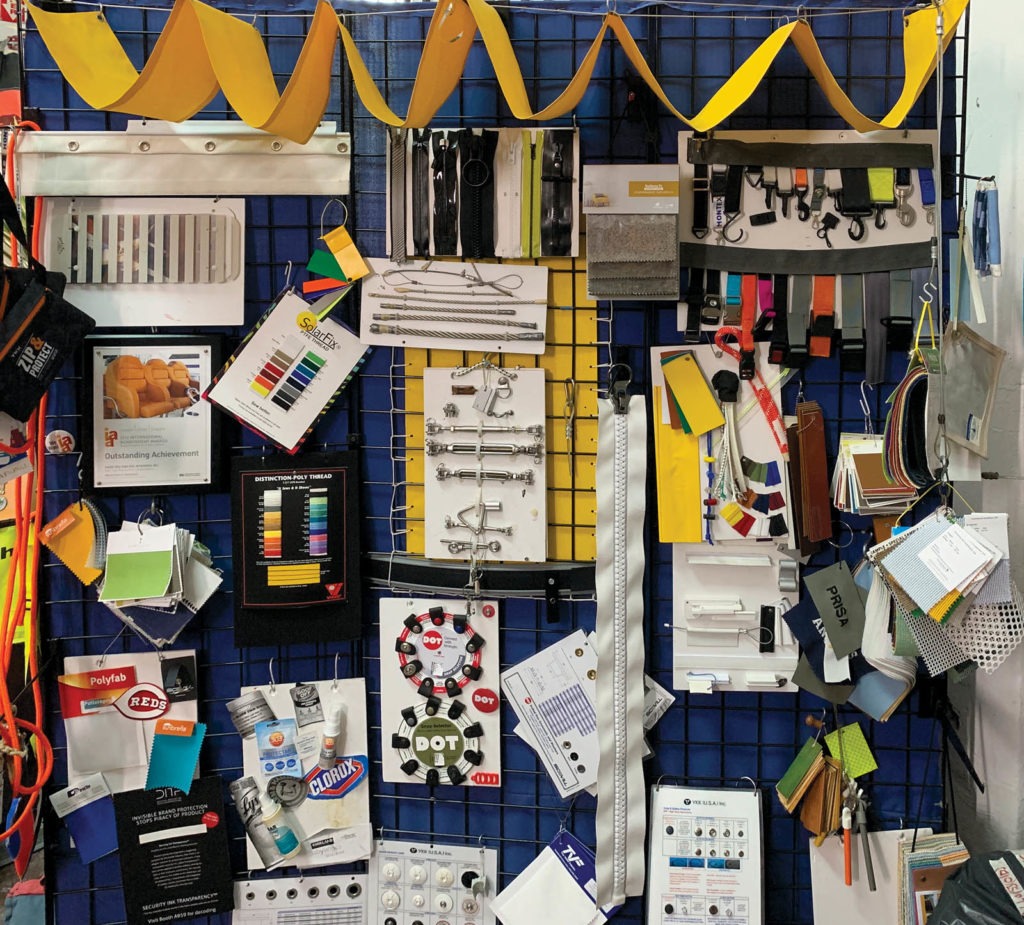

Our company’s goal is to have all materials and hardware required for a project ordered within three days of a deposit. This not only prevents a delay in scheduling production, it also minimizes additional shipping charges and ensures that we have the correct materials on hand. Once a deposit is received and the materials are sourced, we start listing the components for our project board.

It is important to have a designated person prepare the essential information for the project board and place it where your team can easily view it throughout the project. Your projects are only as good as the components included on the project board. Make sure to include all essential details such as deadlines, illustrations, photos, sketches and materials. The board should clarify all required elements for the various stages of construction as well as component hardware and materials.

Keep boards accessible and adaptable

There are many different types of project boards, so design yours to be easy to use in your shop, understanding that it is a powerful tool if taken seriously. In our shop, these boards have become a group activity. They create an inclusive atmosphere at the start of a project and help everyone adapt to the inevitable changes that come along. They are a visual road map from start to finish, and they really don’t require as much time as I initially thought. They help eliminate rework, as steps are outlined with as much or as little information as deemed necessary. You create the path and update the details that cause delays, if necessary. More than anything else, these boards prevent mistakes and wasted time.

Additional benefits

Even if you’re working by yourself, project boards help keep you focused on your big-picture objectives and top priorities. Additionally, they are an invaluable resource for future projects. Having a project archive at your fingertips means you can review, reuse or adapt actual project histories when you create similar new projects. The boards ensure you don’t forget the details and are able to create more accurate plans for future projects. Make sure you have a designated storage space for easy referencing of your project boards once completed.

I am amazed at the difference over time as my resistance lessened and we started creating more visually detailed and thoughtfully designed project boards. When team members are working on multiple projects, these boards eliminate debate and guesswork, which helps them make correct decisions based on the availability of materials, site access and deadlines. For a recent large project of more than 200 planned hours, we exceeded our goal and completed our project in 25 fewer hours. The project board helped team members understand their individual roles in making this happen, from patterning to cutting and sewing to inserting foam and final inspection.

I welcome input from fellow fabricators who use project boards. What visual systems do you use to present new project information to your team in a way that is reliable and easy for them to understand? Shoot me an email at info@sandseaair.com and let me know. May you all stay safe and healthy as we continue to cross uncharted waters.

Terri Madden owns Sand Sea & Air Interiors Inc. in San Juan, Puerto Rico. www.sandseaair.com

SIDEBAR: Project board construction

Keep poster board on hand. We typically use boards that are 28 x 22 inches or 14 x 22 inches. You need enough space to include everything and make it visible across the shop. Designate a team member to assemble, list and keep the project board updated as needed.

Design a unique project scope sheet template for your shop that can be referenced and modified for your projects. Depending on your projects, you may need more than one template.

Include essential information: project scope sheet, illustrations, samples of all components required for the project, photos, materials, hardware, design sketches, quantity of pieces to be fabricated, design features, measurements, samples for approval, names of team members for various stages, installation dates and hours planned for the project versus actual so that tasks can be noted as they are updated or completed.

Upon completion of your project, review and record all details that worked, including changes or details missing from the original instructions, such as changes in materials. Record anything that will make your projects flow easier in the future, such as planned time versus the actual time and customer change requests.

TEXTILES.ORG

TEXTILES.ORG