Competitive edge through technology

Zünd develops high-quality solutions with the goal to keep improving the throughput rate and productivity of their cutting systems.

New software and hardware help fabricators find new efficiencies.

Efficiency and consistent quality are two factors that marine fabricators consider before investing in technology. In addition, the marine industry—and consumers in general—look for customized solutions to meet their unique design needs.

Marine fabricators can look to several companies for solutions to improve their production processes. One such company is Lectra. “Sometimes making it faster can mean a loss in quality,” explains Delitha Morrow Coles, communication manager at Lectra North America. “That’s why our solutions are purpose-built to accelerate development while protecting quality. Our products help fabricators do their jobs faster, more efficiently, and reliably.”

Lectra: Streamlined Design, Prototyping and Production

As the global expert and a reliable partner in the marine supply chain, French-based Lectra strives

to help fabricators find a competitive advantage. That competitive edge depends on fabricators optimizing their production process.

Lectra offers CAD/CAM solutions for fabricators that help streamline their processes for design, prototyping and production. The company often works with marine fabricators to find customized solutions that speed time to market, shorten lead time and lower costs for projects without sacrificing quality.

The latest solutions that Lectra offers include DesignConcept and Diamino. DesignConcept, a complete 2D/3D CAD solution, gives fabricators greater ease and flexibility in product design, virtual prototyping, costing, and technical documentation, as well as enhanced quality.

Diamino provides fabric consumptions for costing purposes and enables “design-to-cost” initiatives. “Used in pre-production and during production, Diamino prepares, executes, monitors and reports on marking activities for improved margins, reduced fabric consumptions, and heightened quality and productivity in the cutting room,” says Morrow Coles.

Vector is Lectra’s automated cutting technology. Vector is suited for an array of technical textiles with complex patterns and designs where precision cutting is needed to seamlessly match edges and curves. Vector’s technology delivers unprecedented uptime, improved speed, enduring reliability and optimized efficiency in automated cutting.

Prodim’s Proliner is a complete digital-templating device for the marine industry. The Proliner can be used for all types of measurements.

Prodim: Proliner

The work of fabricators is mostly based on the custom-made or one-of-a-kind principle. Measuring and making hardboard templates take a lot of time. In addition, there is always the risk of making errors. Prodim International, based in the Netherlands, is the manufacturer and supplier of solutions for professional dimensioning, offering products for several industrial applications; these options include digital 2D and 3D measuring devices and software, production automation (plotter, cutters, CAD and CAM) and 3D printers.

Every specialist working in the marine fabrication industry knows that yacht construction, renovation, restoration and repairs are complex projects. The forms and shapes that need measuring are exceptional, sometimes hard to reach and one of a kind. Prodim’s Proliner allows fabricators to easily measure straight, curved and complex shapes.

“There is a great demand for top-quality measuring tools and CAD software applications. Companies are looking to make their process digital. We currently offer the Proliner, a complete digital templating device for the marine industry,” says Priscilla Jagroep, marketing executive at Prodim.

“The Proliner was developed to be used for all types of measurements. Whether it is a curved teak deck, ship window or door, canvas cover or railing, the Proliner significantly reduces the time needed to measure, digitize and edit. This saves time and money on material and prevents measuring errors, Jagroep explains. “You can measure a ship interior and create your DXF drawing in only minutes.”

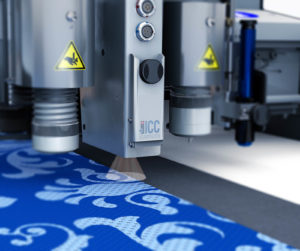

Zünd, the Swiss cutting system manufacturer, offers several lines of digital flatbed cutters, all of which are highly modular and can be tailored to virtually any fabrication/production environment.

Zünd America: Measure Twice, Cut Once

Productivity is a hot topic among marine fabricators. Fabricators want to remain competitive and profitable, produce more work during the same time frame and achieve higher quality at a lower cost.

Productivity can be increased through effective automation and greater process integration. In other words, fabricators need to set up a coordinated production workflow that increases efficiency at every step while keeping waste of time and materials to a minimum.

“When it comes to cutting, Zünd is doing everything we can to help manufacturers achieve this with cutting equipment that is efficient, reliable and very easy to integrate into almost any production workflow,” says Beatrice Drury, director of marketing and communications at Zünd.

Zünd, the Swiss cutting system manufacturer, now offers several lines of digital flatbed cutters, all of which are highly modular and can be tailored to virtually any fabrication or production environment.

As Drury explains, a wide range of modular cutting, routing and even marking tools are available for all kinds of films, fabrics, technical textiles, composites, leather and a wide variety of rigid materials.

“All systems can be configured with the level of automation that perfectly matches the individual fabricator’s production needs—from on-demand, custom fabrication to fully automated nonstop industrial production with robotic loading and off-loading capabilities,” Drury says.

The current Zünd lines include the S3 (generally smaller format), G3 (larger-format, high-performance) and L3 (primarily for leather cutting). The latest line, the D3 series, has even greater throughput capabilities because of its dual-beam construction. The D3 is just in the process of being released.

“Our cutters give marine fabricators the tools to efficiently, reliably and precisely cut the vast array of materials commonly used in this industry,” Drury says. “Given the flexibility and ease of use of our systems, producers can configure them for custom, just-in-time or high-volume manufacturing. We also have software solutions available that help increase productivity and profitability throughout all phases of production, including various nesting options for maximum material utilization.”

Zünd continues to develop high-quality solutions with one goal in mind—to keep improving the throughput rate and productivity of their cutting systems. Zünd solutions include software; faster and more powerful cutting tools, especially designed for specific materials and applications; and material-handling components that keep the system running as much as possible with minimal idle time for setup, changeovers, loading and off-loading.

“We recognize that easy workflow integration as well as data exchange with ERP/CRM systems are key to overall productivity as well,” Drury says. “And with an eye toward sustainability in manufacturing, we put a great deal of care and effort into using only the highest quality components for our systems, ensuring that they keep on producing—literally for decades.”

Zünd automated cutting tables can increase fabricators’ production efficiency.

Carlson Design: Streamlined Solutions

Every year computer aided design (CAD) becomes easier and more approachable. “It’s pretty incredible to think, if you start digitizing your customer’s patterns today, in five years you will have five years worth of patterns stored in a library—5,000 patterns in your pocket, on a thumb drive,” says Thomas Carlson, owner of Carlson Design, Tulsa, Okla. “We think this transition will allow the experienced canvas shops to provide better customer attention.” Patterns will be on file, new covers can be cut quicker, and better pricing can be offered.

Carlson Design offers a complete line of hardware and software to help digitize, draw, nest, and automatically plot and cut textile patterns. The company’s large-bed plotter/cutters range from 36– to 174–inches wide.

“We can provide systems as turnkey or DIY as needed,” Carlson says. “We offer 2D pattern digitizing solutions, free CAD solutions, custom patterning programs, vacuum tables, plans to build your own vacuum table, and full support including installation and training as needed.”

Carlson Design’s most popular new models for the marine industry are the Pro PT-7–inch Plotter/Cutter and Classic CTx-72–inch Plotter/Cutter. “Both feature our universal pen holder and magnetic-mount cutter holder, which can hold our rolling, pinking or drag blade holders,” Carlson says. “And both the Pro and Classic can also be easily configured for our Hot Knife Tool attachment.”

Carlson points out that his company’s automated patterning, marking and cutting systems don’t replace people; instead, these tools make good workers even more efficient. These tools can help fabricators take on bigger projects, quote more competitively, save time and material, and grow without adding personnel.

“We sometimes hear from marine fabricators the sentiment, ‘Everything I do is custom; that system would never help me.’ But usually there are hours and hours of projects every month that are ‘easy.’ We only have to have one or two ‘easy’ hours per week and the system is paying for itself.”

…automated patterning, marking and cutting systems don’t replace people; instead, these tools make good workers even more efficient.

Laser Products: 3D Capabilities and Digital Measuring

Laser Products Industries, Romeoville, Ill., offers a wide range of laser measuring and alignment devices. The company’s LT-2D3D and 3D Disto Laser Templators allow users to three-dimensionally measure any object they come across on a job.

“Our custom software will capture those measurements and allow for the user to turn them into 3D panels,” says Brian Stoiber, director of marketing and support at Laser Products. “We can then flatten those panels into a 2D file that accounts for the warp and weft of specific fabric. This allows the company to use either a cutting table or plotter to produce perfect panels that can then be sewn together.”

Laser Products’ Laser Templators allow the user to measure complex jobs in a matter of minutes and they can measure up to 200 feet away. As Stoiber explains, this greatly reduces the templating time as well as the number of people needed to perform the same task.

“No longer do you need to hand measure fabric panels, cut and sew them to find out you made a wrong measurement,” Stoiber says. “With our lasers, you can see the finished product before you begin to cut anything.”

Stoiber is seeing a huge push toward digital measuring. This is mainly because of the speed and accuracy it offers to companies that employ it.

“There is an upfront cost to it, but once companies who have embraced it see the time they save per job, they would never get rid of it,” Stoiber says. “Our lasers offer a 1mm accuracy, which allows companies to have confidence that when they are cutting fabric, they know every cut will be correct.”

Maura Keller is a freelance writer from Plymouth, Minn.

TEXTILES.ORG

TEXTILES.ORG