Strategies for choosing marine fabrics wisely

When it comes to fabric, the marine environment is unique. Moisture and dirt don’t like most fabrics, and those elements accelerate the growth of mildew, deteriorating fabrics further. Unfortunately, your customers don’t always choose the best fabric, and that’s where you, your suppliers and manufacturers come in.

When it comes to fabric, the marine environment is unique. Moisture and dirt don’t like most fabrics, and those elements accelerate the growth of mildew, deteriorating fabrics further. Unfortunately, your customers don’t always choose the best fabric, and that’s where you, your suppliers and manufacturers come in.

“A boat owner is going to be driven by emotion when picking fabric,” says Cary Williams, marketing specialist at J. Ennis Fabrics. “This can lead them to pick fabrics based on look, rather than look combined with quality.”

Boat owners may not realize that their lifestyles demand higher abrasion resistance or easier cleanability, both of which can be important to the life of their boat interior.

“You need to be educated on the fabrics that you are showing your customers,” says Cindy Boersema at the Nautical Needle in Holland, Mich. “For example, when doing a job that has a lot of curvature you should use a fabric that has flexibility. If you don’t, you will end up repatterning the project.” Boersema experienced this firsthand when she had to repattern a project due to the extreme stiffness of the fabric. “All of the backs I had to split in half, and the helm chair I had to split at least four times,” she says.

All fabrics have limitations that fabricators need to recognize and customers need to embrace. “Certain fabrics will only last so long, but with proper care and maintenance, they will, in some cases, exceed their capabilities,” Boersema says.

In addition to looking at the fire retardancy, cleanability, UV factor and anti-microbial characteristics of fabrics, it is important to determine whether the boat will be in fresh or salt water. “Not only can salt corrode fabrics, but it has an abrasive factor that you need to be aware of,” says Alan Meyers, president of Bainbridge International.

Marine interiors include, flooring, window treatments, seat cushions, upholstery and other fabric-covered applications, and present unique conditions and challenges. There are many types of fabric that work well within these constraints.

Marine interiors include flooring, window treatments, seat cushions, upholstery and other fabric-covered applications, and present unique conditions and challenges. There are many types of fabric that work well within these constraints.

Vinyls: According to Williams, vinyls are the “tried and true” fabrics of marine upholstery. “Of course, vinyls are used a lot in the exterior, but also the interior,” Williams says. “We carry the Softside Collection, Surfside by Naugahyde and our private brand called Midship Neutrals, which is focused on the core whites, beiges and grays.”

Dennis Bueker, branch manager at Tri Vantage in Miami, Fla., says that vinyls offer excellent anti-microbial properties, and resist mold, mildew, insects, chemicals and oils. Meyers agrees. “Vinyl is available in a variety of colors, textures, and embossing,” he says. “We offer a tremendous number of different types of grains and backings for our vinyl fabrics.”

Vinyls are made of 100-percent polyvinyl chloride, with backing content of 100-percent polyester. This type of material offers excellent strength, abrasion resistance and low absorbency. Vinyls will not absorb fluids, and are easy to care for because they resist mildew and mold. Bueker notes that a drawback of vinyl is that it does not offer the breathability of other fabrics.

Polypropylene: Also called polyolefin, industry experts agree that polypropylene fabrics provide a wealth of characteristics that make them suitable for the marine industry. “Polypropylene fabrics resists deterioration from chemicals, mildew, perspiration and rot,” Bueker says. “It is also the lightest weight of all fabrics.”

Polypropylene fabrics offer insulating characteristics, high wicking properties, and are stain, static and odor resistant. Polypropylene can be an expensive choice for some customers.

Rayon: Rayon is a regenerated cellulose fiber that burns rapidly. Compared to vinyls and polypropylene, rayon provides fair to poor mildew resistance and dimensional stability. According to Bueker, when rayon gets wet, it actually loses 30 to 50 percent of its strength. In addition, rayon can shrink, causing significant problems with upholstered items.

Synthetic leathers: Considered by many to be the “original” polyurethane upholstery fabric, Ultraleather is strictly an interior product. As a faux leather it is suitable for marine use. “The hand on this product is still the best on the market and it blows away every fabricator and boat owner who touches it,” Williams says.

Considered by many to be the “original” polyurethane upholstery fabric, Ultraleather is strictly an interior product. As a faux leather it is suitable for marine use. “The hand on this product is still the best on the market and it blows away every fabricator and boat owner who touches it,” Williams says.

Made of 100 percent polyurethane, with a backing of 100 percent reinforced rayon, Ultraleather is stain and soil resistant and is waterproof. Its abrasion resistance typically exceeds 400,000 double rubs.

Triacetate and acetate: Most triacetate resembles acetate, but is less sensitive to heat. This characteristic allows triacetate fabrics to be crisply pleated or creased. In addition to offering a luxurious feel, triacetate offers good dimensional stability, and most triacetate fabrics can be machine washed and dried.

Acetate fabrics offer a crisp, soft feel. However, acetate fibers melt in temperatures over 300 degrees. Nail polish, paint remover and some perfumes will dissolve the fibers.

Acrylic: Resembling wool’s softness and bulk, acrylic fibers are blended with wool or polyester fibers. Offering excellent wicking properties, acrylic is resistant to moths, mildew, oils and chemicals. And while acrylic provides good dimensional stability, it has a tendency to pill.

When Boersema at the Nautical Needle works with her clients, she always recommends a product that can withstand the sun, water and tanning lotion. Boersema favors Glen Raven’s selection of acrylic fabrics. “The fabric is 100-percent solution-dyed acrylic and has a fluorocarbon finish and a three-year limited warranty,” she says. “Bleach will not harm this fabric, and spills are easily cleaned with a damp cloth. Robert Allen also has a performance fabric that is 100-percent solution-dyed polyolefin. In addition to being 100-percent stain resistant, the fabric features 1,500 hours of lightfastness, 50,000 double rubs, permanent mildew resistance, water repellency and is resistant to pilling.”

Cotton: While cotton offers a soft, comfortable feel, many cottons have fair to poor dimensional stability and moderate abrasion resistance. “Look for fabrics that are made of combed cotton,” Bueker says. “They have longer and smoother fibers that will stand up better to abrasion.”

Because of mildew concerns, Meyers sees many marine fabricators shy away from using cottons on areas of boats that will be exposed to moisture.

Suedes: As has been the trend in home décor, more and more industry experts are seeing microsuedes used in boat interiors. “Suedes are very easy to clean and provide a great texture and look,” Williams says. J. Ennis Fabrics carries the original “Irresistible” that started the microsuede movement in home décor in North America, as well as “Impulse,” which has a different pile height and back. Do not place suede in direct sunlight.

Leather: Natural leathers are often used in upholstery applications, but because of the unique elements found within the marine industry—namely salt, suntan lotion and water—leathers need to be treated with anti-mold agents and bactericides.

Solution-dyed acrylic: Indoor/outdoor fabrics, such as those offered by Sunbrella, are strong enough for the outdoors but decorative enough for interiors. “As North Americans continue to expand their living rooms into the outdoors, these materials are huge in home décor right now,” Williams says. “Because of Sunbrella’s trusted name and quality, we are seeing those patterns cross over into marine applications.”

Sunbrella fabrics are ultraviolet resistant and mildew resistant. They are treated with a stain and soil finish, which adds to their oil resistance and water repellency.

The abrasion resistance of Sunbrella’s Horizon fabric exceeds 18,000 double rubs. It can be spot washed by sponging with a solution of natural soap in lukewarm water.

Crypton: Crypton is well known in the contract market, but Williams thinks it’s only a matter of time until it crosses over to marine interiors. “The permanent moisture barrier that Crypton provides makes it easy to clean and great for interior marine environments where the boat owner may have concerns about seats getting wet.”

As far as drawbacks, breathability is an issue with Crypton. That’s why Williams recommends that upholsterers add a mesh pocket or use a seat bottom lining to allow air to escape. Made of 100 percent recycled polyester, Crypton is engineered to provide permanent moisture and soil resistance and anti-microbial protection.

Nylon: For decades, nylon has proven itself in marine applications. It’s extremely strong, smooth, lightweight and non-absorbent. Nylon knits, although stretchy, will recover their original shape because of their dimensional stability. “Nylon offers various hands, some that feel crisp and slick, others that feel soft and luxurious,” Bueker says.

Linen: There is nothing quite like the feeling of crisp, cool linen on a hot summer day. And while linen offers good dimensional stability and strength, it does wrinkle easily. Some linen fabrics can be quite absorbent—leading to mold and mildew concerns in marine applications.

Wool: Most industry experts agree that wool is not the most appropriate fabric to use in wet, sun-drenched environments. That’s because wool is not only highly absorbent but it also is not resistant to the sun. If wool is the fabric of choice for your marine customer, be sure to use the highest-quality wool available. And make sure the application is well ventilated and kept clean.

Green fabrics: Williams is seeing “green” fabrics making strides in the interior marine marketplace.

“We’re seeing green become an important trend in marine, as we have in home décor,” she says. “Many motor companies are promoting more fuel-efficient and less-polluting motors, and of course, sailing is the original green transportation method, so we see the eco movement crossing into interior fabrics very soon.”

Care and maintenance

No matter what fabric you choose for a particular application, all fabrics have different and specific care and maintenance requirements. It is important to provide your customers with cleaning instructions upon the completion of a job.

Industry experts recommend providing a cleaning kit that explains proper cleaner applications and techniques. Boersema provides every customer with a laminated sheet of cleaners to use and not to use.

“All fabrics have a cleaning code, and it is there for your use,” Boersema says. “If I am using a fabric in an application that I have never done before, I will do a test on the fabric to make sure it’s compatible. Remember, the better care given to the fabric, the longer it will last.” And the happier your customers will be.

Maura Keller is a freelance writer and author based in Plymouth, Minn.

Strategies for selecting fabrics

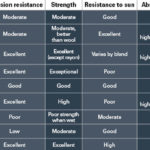

Dennis Bueker, branch manager at Tri Vantage in Miami, Fla., says that, when choosing fabrics for interior marine applications, it is important to consider such things as fiber type, absorbency, abrasion resistance, care requirements, pattern, environment and color fastness.

You also want to ask customers these key questions:

- How often do they use the boat?

- How long is an average excursion for them; are they living on the boat for days or weeks at a time?

- Do they spend more time sitting inside or above deck?

- Is the fabric going to be in direct sunlight?

- Will they be sitting on it with wet swimsuits?

- Are there any design changes?

- Will young children be on the boat?

- Will the boat be used in fresh or salt water?

- What problems might be encountered?

- How will it be attached?

TEXTILES.ORG

TEXTILES.ORG