The science of vinyl discoloration

How it happens & how to prevent it

Look around a typical marina during the summer months and you will see dozens of vessels—some new, some old, some big, some small, and perhaps a few that show signs of transient color changes in the PVC fabrics being used.

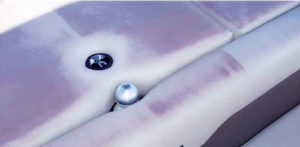

For more than 50 years, PVC discoloration, also called “pinking,” has perplexed the marine industry. Vinyl and fabric manufacturers, marine fabricators and boat owners alike are eager to pinpoint the problem and find a solution.

The primary cause of discoloration is the migration of trace chemicals from adjacent materials laminated to the PVC.

Recently, Glen Raven Custom Fabrics embarked on a scientific investigation into the cause of the pinking phenomenon, hoping to uncover ways industry players can prevent and treat transient color change issues in the future. Glen Raven hired Dr. Duane Priddy, founder and CEO of the Plastic Expert Group & Failure Labs Inc. in Midland, Mich., to study the pinking issue to determine key causes and subsequent prevention techniques.

“This is not a new phenomenon,” says William McDaniel, marine market manager at Glen Raven Custom Fabrics in Glen Raven, N.C. “It was first noticed back in the early 1980s in the United States. Investigations then pointed to compounds that were removed from vinyl production and the problem pretty much went away. In recent years, we have seen a greater influx of imported vinyl that uses the same compounds, and the problem has reared its ugly head once again.

“The causes have been attributed by some to the fabric, across all product lines and categories, as well as to many other factors. We wanted to ensure that it isn’t a fabric issue, so we set out to determine the cause through this study.”

Defining the phenomenon

Although often called “pinking,” vinyl discoloration can take on myriad hues, including yellow, orange, blue and pink.

According to Priddy, the primary cause of discoloration is the migration of trace chemicals from adjacent materials laminated to the PVC. “For example, when PVC is laminated to polyurethane foam, trace amines in the polyurethane migrate into the PVC, catalyzing degradation of the PVC,” he says. “The rate and extent of the discoloration is facilitated by heat and humidity. The discoloration is somewhat reversible and the color may fade upon exposure to sunlight.”

Mike Von Wachenfeldt, technical service manager at Glen Raven Custom Fabrics, explains there are several issues that might cause discoloration on marine vinyl upholstery. These may include mold, mildew, a breakdown of the PVC (dehydrochlorination), interaction of additives in PVC formulations, as well as the pinking phenomenon. Also, the interaction of PVC substrates with other types of substrates, whereby chemicals between the substrates migrate in conditions of high heat and humidity, facilitate transient discoloration.

There are many potential causes for discoloration on marine upholstery, up to and including stains from consumer use. “The problem is most common, but not exclusive to, the Southeast,” says Terry Mead of Spradling International Marine, a manufacturer of vinyl and vinyl-coated seating fabrics in Grand Rapids, Mich. “The stain generally takes some time to develop and it can be small in the beginning and often starts in the areas around the seams, where dirt enters,” Mead says. “With a properly constructed seat, which includes treated components, the stain may never occur. In addition, care and cleaning of the upholstery is directly related to the development of the pink stain.”

Performance factors

Mildew manifests itself in a wide array of colors, including yellow, green, black and brown; but marine mildew often shows up as a pink blotch, which is why mildew is termed “the pink guy” in marine circles.

The discoloration can be mild to severe, depending on several factors including the age of the vinyl, the amount of exposure to direct sunlight and subsequent ultraviolet rays, the heat generated in the environment where the boat is stored and whether the boat is stored outdoors under a cover or in an enclosed garage where heat is allowed to build up.

“A covered boat with proper ventilation, that protects the upholstery from the ‘greenhouse effect,’ rain and other elements, makes a significant difference on the performance of the upholstery and resistance to the pink stain,” Mead says.

The time it takes for the discoloration to show varies by situation. “For example, it can occur gradually over a period of time, but may happen quickly, in a day or over a weekend, when aged vinyl is exposed to extreme heat,” says Alan Rampey, Glen Raven’s director of technical services.

Where the discoloration occurs most frequently has more to do with the specific vinyls and components used, such as foam and adhesive, rather than the specific use of the product.

Testing reveals that discoloration can happen under virtually any type of cover—acrylic, polyester, cotton, vinyl and blends—or no cover at all. But heat buildup in the boat (150 degrees F or higher) no matter the source, is the key component.

Causes of the color

While the pinking issue is a hot topic within the marine industry, it is not exclusive to marine applications. The pinking phenomenon occurs in automotive vinyl applications, vinyl siding, windows and door trim. And it has occurred across a variety of coated, laminated, rubberized and water-repellent fabrics.

According to Von Wachenfeldt, studies show the pinking issue is related to chemical reactions from trace amines in the foam and adhesives that bond the foam to the upholstery vinyl migrating into the upholstery vinyl and reacting with compounds (such as phthalates, which are used as plasticizers) in the vinyl to produce a colored compound, a chromophore (pink in this instance).

“It is an unstable bond and will be broken down with exposure to UV rays,” Von Wachenfeldt says. “This is why the upholstery vinyl may often turn pink when covered and exposed to heat buildup. But when exposed to direct sunlight, it may diminish significantly or even go away completely. Depending on the amount of ‘free agent’ compounds in the vinyl, this may or may not recur.”

While mold and mildew-related issues can often be cleaned, dehydrochlorination (browning produced by heat exposure and vinyl aging) and pinking are chemical reactions within the vinyl, so cleaning is not an option.

“Once PVC has degraded or discolored, it is impossible to totally restore the PVC to its original color,” Priddy says. “The use of bleach will cause the discoloration to fade somewhat, but it will not totally restore the original color.”

Prevention techniques

So how can the discoloration be prevented in marine applications? Certain vinyls will be subject to the pinking phenomenon depending on the chemical makeup of the vinyl.

A vinyl’s composition is the key to a stable product that remains free from chemical changes and the resultant undesired discolorations. A vinyl product not optimally formulated against its environmental stress factors and aging can chemically degrade and produce an array of colored shapes—from small spots to large splotchy areas to a more uniform solid appearance.

Priddy says the best way to stop PVC discoloration is to laminate only those materials to PVC that are fully compatible with PVC. “The laminant material must not contain trace chemicals that catalyze PVC degradation,” Priddy says. “For example, instead of using polyurethane foams, use polyolefin foams to laminate with PVC. Polyolefins do not contain traces of amines.”

Von Wachenfeldt says that if the pinking is a result of a chromophore, a chemical bond in the vinyl, exposure to UV light for extended periods may eliminate or greatly reduce the visible discoloration. “At that point, venting, padding, or suspending the cover over seating to increase airflow and reduce temperatures in the vinyl may prevent or at least reduce the severity should it recur,” Von Wachenfeldt says.

The scientific study Priddy performed resulted in additional key approaches by manufacturers in solving the discoloration problem: eliminate chemicals from non-PVC fabrics that migrate into PVC fabric, causing it to discolor; and change the formulation of the PVC fabric to make it more color-stable when exposed to other textiles.

There also are steps that fabricators can take to greatly reduce the likelihood of its occurrence.

“Venting of the cover will allow hot air to escape from underneath the cover,” Rampey says. “Heat rises so vents at the high points of the cover are best. There are some solar-powered vents available that are equipped with fans to enhance airflow out from under the cover.”

Elevating the cover fabric from direct contact with the vinyl will also allow for airflow underneath the cover and will prevent high heat buildup in the vinyl itself. Rampey suggests another layer of fabric or perhaps a nonwoven backing might help, or something as simple as placing a swimming noodle under the cover on a boat deck to elevate the cover and increase airflow.

Spradling has taken a unique step in regard to the pinking problem. The company has created a list of criteria, which, when met, triggers the product warranty to include compensation in the event of pink staining in marine upholstery.

“This is an aggressive stance, but one we believe is needed,” Mead says. “The pink stain problem is not the responsibility of any single supplier or of the manufacturer, and, with education, the problem can be reduced greatly.

“If a seat is properly constructed, with the right materials, and cared for properly by the dealer and the boat owner, pink staining is not likely to ever be an issue.”

Maura Keller is a freelance writer based in Plymouth, Minn.

TEXTILES.ORG

TEXTILES.ORG