Work smarter, not harder

Have you ever witnessed a unique method used by an industry colleague and thought to yourself, “That’s so simple—why didn’t I think of that?”

This is the concept behind the Tools, Tips and Tricks contest, which the Marine Fabricators Association (MFA) runs every year at the Marine Fabricators Conference. Business owners and employees share something that has made their shop life easier, and attendees vote on which three will win a prize.

Submissions are often met with praise when presented at the conference, but they rarely get wider visibility. We’ve compiled a small selection of our favorite submissions and winners from the past few years because they are worth showcasing.

Hopefully you find one idea that makes your job a little less cumbersome. If you have your own tool, tip or trick to share, enter it in the 2026 contest.

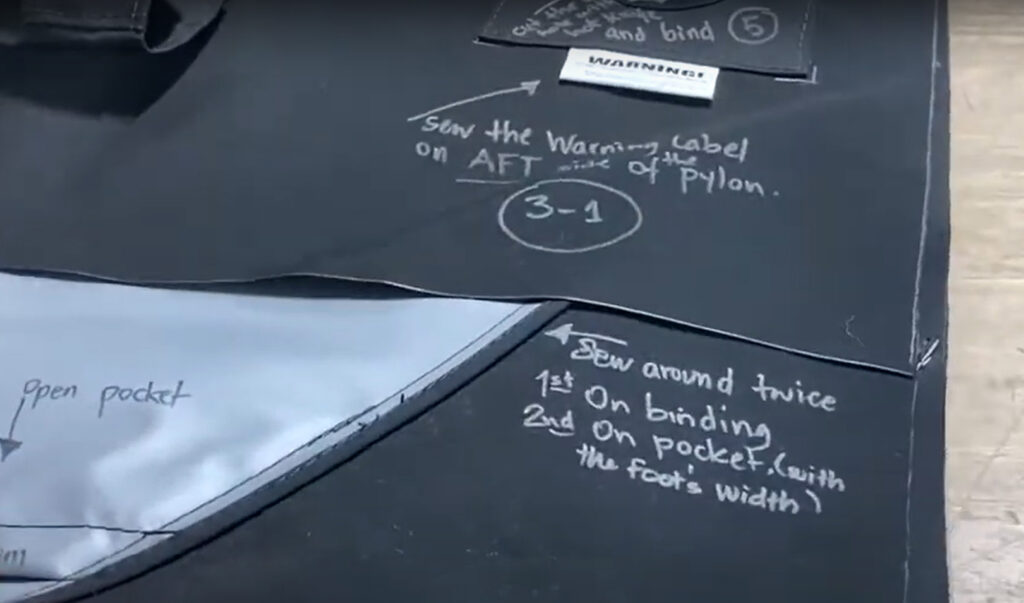

Sample Boards

By Justin Jones, SewLong Custom Covers in Salt Lake City, Utah

SewLong Custom Covers uses sample boards to set shop standards and teach employees how to make the company’s products. The shop built a sample board for each type of project an employee may need to complete.

“You can flip through the different pieces and be reminded of the standard we have set,” says Jones. “We had a product that we made about once a year, and our team kept making the same mistake year after year. So our first sample was twofold: An example of how NOT to do it (the mistake we kept making) and how to do it right.”

There are 10-15 total sample boards. Five to seven of the boards are dedicated to products the shop regularly sells, like covers. A handful more demonstrate generic fabrication standards, like different edge finishing techniques. The remaining boards show off random projects or techniques the shop does occasionally.

Written notes and arrows explain the steps and why they must be done to meet company standards. This is particularly helpful if it’s a type of job employees haven’t completed recently or don’t typically work on.

“The idea is that the boards should evolve with the company,” says Jones. “As we learn and try new things, the boards should evolve as well.”

Double Needle Trick

By Shane Cossette, TRS Industries in Fargo, N.D.

Cossette uses double needles for sewing webbing onto awnings, canopies and tarps. These needles were designed by his father in the late 1980s.

“We had just started building truck tarps that required webbing and D-rings to be sewn around for attaching,” says Cossette. “We were sewing around the tarps two times with a single-needle machine.”

The webbing used in the shop is 2 inches wide, so TRS Industries uses a 1 and 1/4-inch gauge double-needle machine with custom-made guides and a webbing roll holder. From there, the shop installed an aftermarket pedal for reversing.

Cossette estimates that this tool cuts the shop’s sewing time in half. The guide made for the machine and other process improvements have only enhanced efficiency.

“Not only are we sewing our webbing in one pass, but we backstitch over the D-ring straps without taking our hands off of the fabric,” says Cossette. “Once you get the webbing loaded into the guides, it feeds itself so the operator can just focus on following the line.”

Welt Scissors

By Doug Buuck, All Marine Canvas One LLC in Punta Gorda, Fla.

These scissors were built for the shop over 40 years ago and are still simplifying projects today.

Buuck designed them per his needs and using specifications provided by his sewing machine repairman in Fort Wayne, Ind., in the 1980s.

The scissors were made with the guide to cut 1 and 1/2-inch of fabric, wrap it around a 4/32-inch welt and sew it, to provide the exact amount needed for a 1/2-inch seam.

“It’s a one-step process, as opposed to having to measure and then cut,” Buuck says. “Using a straight edge on vinyl, cloth or Sunbrella®, you are literally able to walk down the side of the cutting table and cut as much welt as needed in a very short amount of time. They are used often in our shop.”

Buuck estimates that the scissors reduce the cutting time by half for each job. The market has yet to produce a similar solution, to the best of Buuck’s knowledge.

For more information on this unique pair of scissors, contact Buuck at +1 941 626 6627 or email at allmarinecanvas1llc@gmail.com.

Daytona Wheeled Dolly

By Mike Boatman, Boatman Marine Canvas in Oklahoma City, Okla.

This dolly holds up to 1,300 pounds. Boatman says it’s perfect for “when you need to get that car or boat in your shop in just the right spot to provide you with extra space.”

“Buy the ones with the nice, metal rollers, because the plastic ones will break,” he adds.

Place one dolly on each of the boat trailer’s wheels, click the dolly in, raise the wheels off the ground and get the dollies rolling in the same direction. It offers the extra 1-2 feet of shop space needed once the boat is pushed into the corner.

The dolly won’t work in every situation—heavy surf boats won’t move, for example—so some boats will always be a bit in the way. But for boats that can be moved, having the dolly on hand can make a world of difference.

Boatman recommends spending about $50 to get the wheeled rack, which holds all four dollies, because it “makes it easy [to] wheel around the shop.”

It’s worth noting that one likely reason for Boatman’s success in the contest is his showmanship. Make sure to check the Tools, Tips and Tricks archive to see his and all other project videos in this article!

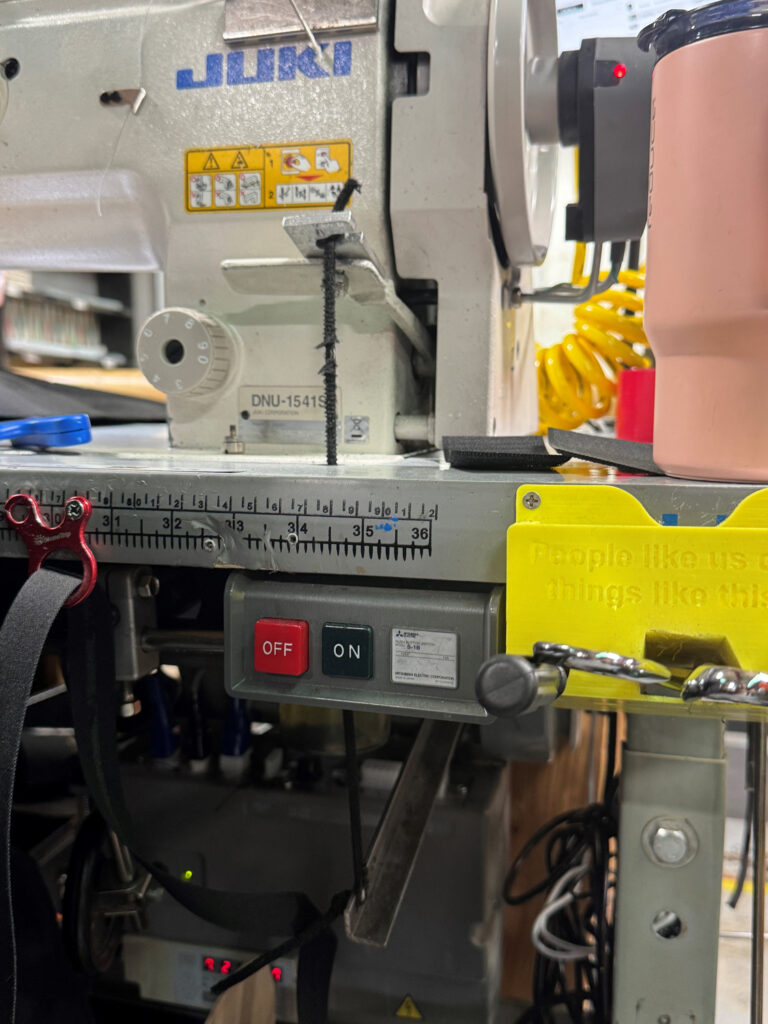

Reverse Foot Pedal

By Justin Jones, SewLong Custom Covers in Salt Lake City, Utah

Jones designed this pedal to be outfitted to every sewing machine in the shop.

The idea originated with Jones’s father Jack, of Jack’s Do-It Shop. He installed the pedal on an old Pfaff® machine that required sewers to move the lever up for reverse stitching; he put a cable over the top of the machine that attached to the foot pedal, so as he pushed down on the pedal it pulled up on the lever.

“As I ran my own shop, making seat covers that required a lot of back tacking to hold the ropes in place, I added a modified version to the Consew® machine I was using at the time,” says Jones. “Then as I started making boat covers and upgraded machines to Juki®, we added to those machines. Most of our machines now are computerized with automatic back tack and, when needed, have a button for reverse.”

Typically, when sewing backwards, fabricators must take one hand away from the fabric to move the back lever. The Reverse Foot Pedal executes this same task while keeping both hands steady on the material, saving hours of time.

“My left foot was going numb as it was the only limb not doing anything, so it helped me utilize one other limb. Like learning to drive a stick shift, it takes a little getting used to it, but once you know it, it saves time and energy,” says Jones.

The pedal is attached to a chain, which is connected to a bar that stretches across the bottom of the machine. At the end of the bar is a rope that secures to the back lever. The result is a pully system that back-sews with the foot.

Lil Weggie

By Mike Boatman, Boatman Marine Canvas in Oklahoma City, Okla.

Boatman purchased this tool from Get A Grip Inc. It will grip onto material and fabricators can tie a rope to the other end. From there, pull up whatever is needed.

“You might not need a lil Weggie often, but when you do, it is fun to have,” Boatman says.

The lil Weggie is made of heavy-gauge stainless steel, a convex tension spring and polycarbonate with UV protection. The product is welded together using sonic welding technology. Dual-billet aluminum rollers with a touch of knurling gives them bite, riding on over-sized axles.

The locking system is operated with a thumb pad, and the lil Weggie has ample opening to grasp several layers of tarp at once. Its honeycombed housing reduces weight and adds strength, and an oversized trapped bell eyelet maximizes versatility.

Boatman primarily uses the lil Weggie on occasions when the shop is trying to get material up and over a T-top that can’t be easily accessed.

“You can tie on a rope, with a little weight at the end, to throw the rope over the end of the object you’re trying to get the material over,” he says.

Folks who want to buy their own can visit LILWEGGIE.com.

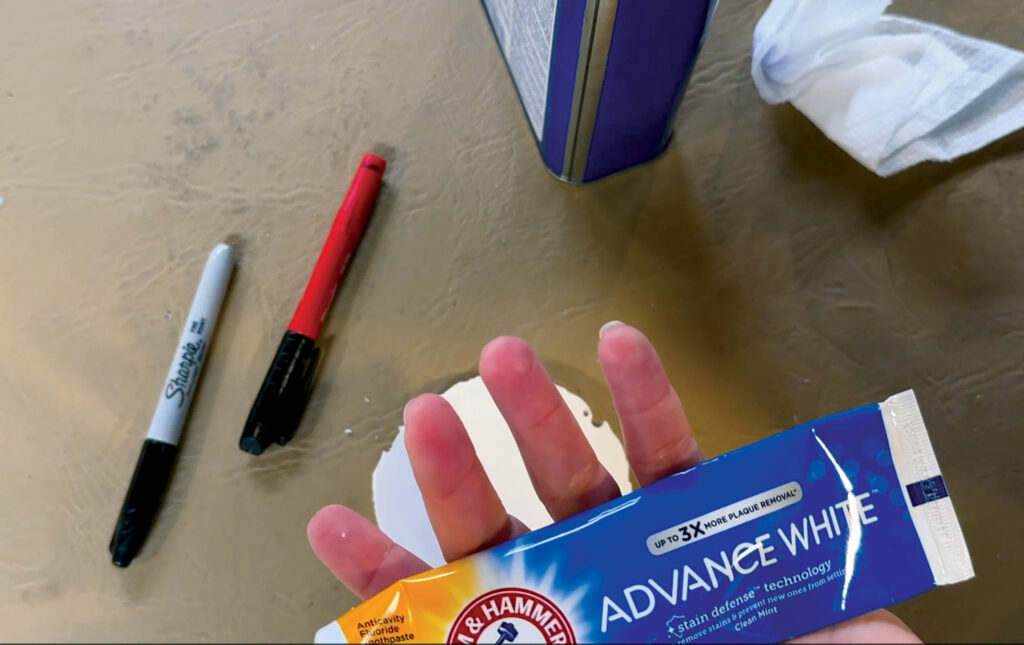

Removing Permanent Marker

By Keri Ames, Yachtsman’s Canvas in North Wales, Pa.

On your mark, get set … oops! This trick should be relatable for any marine fabricator.

“We’ve all run into the issue of accidentally getting permanent marker on our customer’s boat,” says Ames. “This is an effective method for fully removing marks from the fiberglass.”

Apply acetone to start, but don’t panic yet—it will get a lot worse before it gets better. Next, apply Arm & Hammer® Whitening Toothpaste, which contains baking soda. Finally, wipe down with more acetone.

“Depending on the condition of the fiberglass, you may need to repeat the process to fully remove,” says Ames.

She experimented heavily to find the most effective method. Past products she tested include denatured alcohol, hairspray, nail polish remover and Deep Woods OFF!® insect repellent. These chemicals lightened marks, but never fully removed them.

This trick is not specific to any brand—Ames demoed the trick on Sharpie® and Milwaukee® permanent markers.

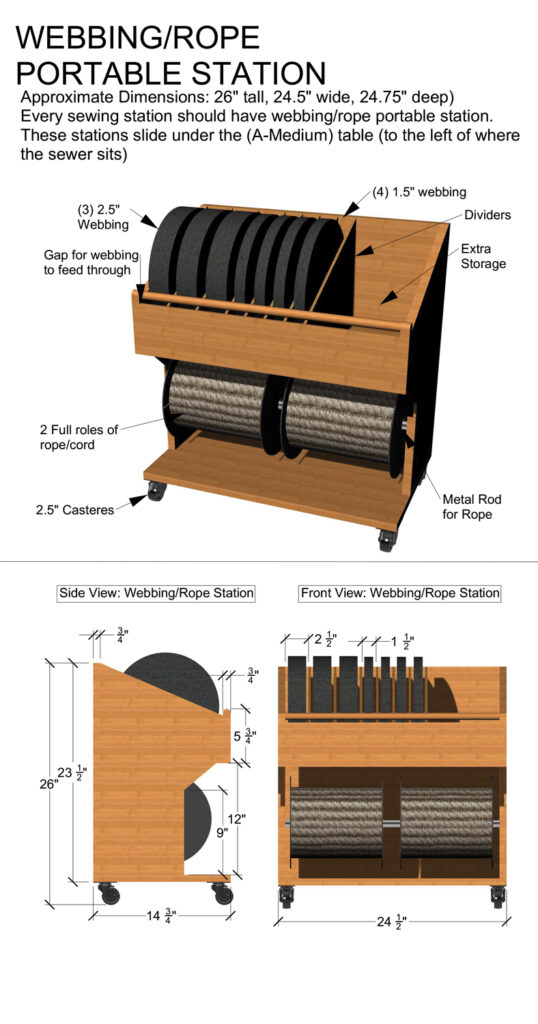

Webbing Box

By Duniuska Mota, SewLong Custom Covers in Salt Lake City, Utah

The Webbing Box has the potential to solve a few problems in a shop.

Mota initially developed the idea and worked with the rest of the team to produce the final product. Each box is constructed with vertical slats to establish dedicated spaces for each roll of webbing and Velcro®. One larger section at the end of the row holds bombshell covers.

At the front of each section is a small, horizontal slot where webbing and Velcro can be fed through. This prevents rolls tangling throughout the day. Below the slat is a piece of Velcro, where fabricators can stick the end of the roll to when not in use. This prevents large strips hanging from the side of the box.

The Webbing Box is a big upgrade from housing webbing on a shelf or in cardboard boxes, which is how SewLong was storing its webbing beforehand. The box offers clean organization, is easy to use and helps maintain the stock at each sewing station with webbing, hook and look straps, and boat vents.

“We don’t have to fight with our webbing, and we know where all of it is,” says Mota.

The shop has redesigned the box as part of a whole sewing station “pod” concept, which is slated to be implemented in the off season. The new iteration of boxes—pictured above—are taller and on wheels, and they include a pipe for wider rolls (i.e. ropes).

TEXTILES.ORG

TEXTILES.ORG