Cushion styles—design and function

By Terri Madden

As you read this, I hope you’ve written down and are applying the goals you targeted for 2015. It is an insurance policy to glean the benefits of the goals you’re focused on and is a win/win solution for success in 2015.

An interesting comment that stuck with me from a recent conference was “saying ‘No’ to a customer.” WOW—it was liberating just to think about it, and I actually used it in response to a request from a customer I had not seen in more than five years. He told me he’d given the easy things on his list to other fabricators, yet wanted me to fabricate a very difficult project for him. It was one of my least favorite projects and it would have required substantial travel time. It was refreshing to say “No”—though I did provide a referral to another fabricator.

Think about it and trust that a rewarding project is “waiting in the wings.” I believe our intuition warns us when a customer request goes against our grain, even if it always does seem to occur during a lull and when we need the work.

Think about it and trust that a rewarding project is “waiting in the wings.” I believe our intuition warns us when a customer request goes against our grain, even if it always does seem to occur during a lull and when we need the work.

Most MFA projects seen at the National Convention in Oakland in January were executed with impressive skill and to customer satisfaction. Others could have been approached differently if the fabricator had the foresight that generally comes with experience in this specialized field. There are hundreds of designs and styles for cushions. For your next project, evaluate how complex it is. Determine if you are willing to put in the time to do the research and create the samples necessary to achieve the required result if the project is new for your skill level. In the end, you want your workmanship to be outstanding. Following are a few projects that pushed my skills to a new level.

A corner cushion

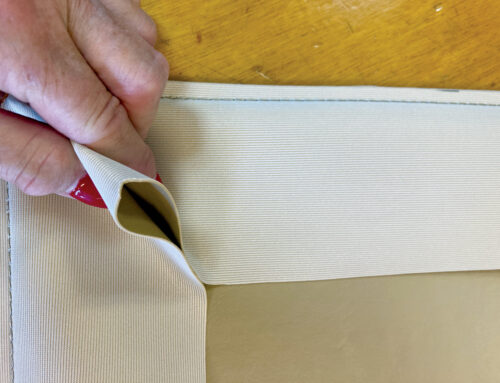

One customer had a corner bridge cushion fly off the boat. Rather than fabricate a new cushion exactly as the original, we used the opportunity to design a new cushion with a 3/8-inch PVC back. The PVC was carefully heat molded to the hull shape. Two-inch marine foam was used, and the vinyl top/lower bands were patterned to the curve contour. We installed upper and lower rows of 1-inch Velsticks mounted to the fiberglass, and 2-inch marine Velcro was sewn on the mesh back of the cushion. The cushion (above) was securely held in place by almost 100 percent contact versus only a few original snaps.

Hinged cushions

I could have included several sketches, calculations and directions for fabrication of hinged cushions that are often requested for boats, hospitality and residential chaise cushions, yet I think this Sailrite video link “How to Make a Hinged Back Cushion” clearly demonstrates what is difficult to put in print.

I could have included several sketches, calculations and directions for fabrication of hinged cushions that are often requested for boats, hospitality and residential chaise cushions, yet I think this Sailrite video link “How to Make a Hinged Back Cushion” clearly demonstrates what is difficult to put in print.

The video demonstrates step-by-step how to create a large cushion with a hinge that serves as both the back and seat of a chair. Deck chairs on large vessels are often requested, and you will find this video helpful as it walks you through fabric patterning, sewing, cutting and inserting the cushion foam. The project also includes an optional attached pillow for the top of the cushion.

Over the years, Sand Sea and Air has adapted the style shown, so I have included descriptions and a few photos of styles that were customized to meet requests with specific parameters for size, function and storage:

Three-section cushion with double hinge

Three-section cushion with double hinge

Hotel Casablanca, San Juan, Puerto Rico – Aligning the stripes on these chairs (above left) increased the level of difficulty on this multisection hinge cushion. Since the final cushion was divided into three sections, each section was constructed individually with zippers and a 2-inch fabric hinge band at the cushion transitions. Each band had to be carefully incorporated into the sewing process of the corresponding cushion. The cushions were constructed and sewn in this manner to provide optimal raising and lowering of the cushion sections while in use. One-inch tie–down straps were added to secure the cushion to the frame on a very windy deck.

Multisection hinge cushions with piping

Sailing vessel True Blue – Contrast piping also increases the level of difficulty. These cushions were fabricated in Marine Vinyl with mesh backs utilizing 1-inch closed-cell foam. The parameters included cushions that would conform to the contours of the boat while being easy to fold and stow in the limited space offered by deck storage compartments. The cushion sections were constructed separately and joined in a manner similar to the above project for the full cockpit of a classic 54-foot Sparkman Stevens sailing vessel. They could have fit in a large pizza box, yet provided spacious seating and comfort to the owner who had severe back problems.

Double-section hinge cushion with stitching and grommets

Double-section hinge cushion with stitching and grommets

Hotel El Convento, San Juan, Puerto Rico – In addition to the challenges of working with striped fabrics, the contour of the frame in the raised and lowered positions increased the level of difficulty. This cushion was constructed in a manner similar to the cushion in the video. It had one length of fabric for both the front and the back. The center area, where the cushion frame transitioned, was the area designated for the division of the upper and lower cushion sections. The area between the upper and lower cushions was defined by parallel stitching divisions. Additionally, grommets were added within the center area to deflect rainwater build-up as the seating was used both for guests during daytime sunbathing as well as evening social gatherings.

Add value

Add value

These seating styles and more can be sourced on the Internet, and if seating and cushions are the bread and butter of your business you should start a file of the images to source, evaluate and adjust to your customer requests. Additionally, almost all seating should include pillows for extra comfort and specialty fabrics that provide a dramatic visual impact. Offering pillows is a value-added point of sale that your customers will appreciate.

No matter what type cushions your customer brings or attempts to explain to you, I have found it essential to review the major details when approaching a boat cushion project for estimation, fabrication and installation.

Terri Madden owns Sand Sea & Air Interiors Inc. in San Juan, Puerto Rico. www.sandseaair.com

TIPS:

Re-do or new configuration? Know what you can do and how to improve upon the original design.

- Where and how will a cushion(s) be used?

- How will it be held “in place”?

(Snaps, Velcro, Fastmount etc.) - Will the covers be removable for cleaning?

- Will the cushion be a soft base or PVC?

- Materials—Vinyl, leather, fabric, mesh etc.

- Pattern alignment—Especially for bands and corners

- Style—Quilted, Hi-Lo, banded, roll-over,

baseball corners etc. - Seams—Simple seam, topstitching, piping etc.

- Thread—Polyester, PTFE, weight of thread

(heavy accent stitching). - Foam—Original, new, Poly, E-Z Dri, closed-cell.

- Zippers, Velcro, Velstitck, hardware, webbing,

Stainless Staples. - Refer to past issues of Marine Fabricator for articles offering good advice and photos on patterning and construction.

- Take photos before, during and after every project.

Having all of these details confirmed by the customer and available on a form clarifies the scope of a job. It assures the fabrication process runs smoothly and results in an award-worthy project for you and your customer. Consider each project as a future entry for an MFA Excellence Award in 2016. It is a realistic goal to believe that your next project—which you’ve designed and executed with your unique skills, input, attention to workmanship and functionality—can be an award-winner.

Your greatest reward is a repeat customer who will be your best referral advocate for your business!

TEXTILES.ORG

TEXTILES.ORG