Working successfully in tight interior spaces

By Terri Madden and Alayna Wool

Before signing a client contract for a new interior project, it’s important to consider any unforeseen obstacles you might encounter on the job. This will help you surpass your client’s expectations and prevent profits from withering away due to having to work overtime. Pre-production communication is key to a successful installation in tight spaces. By forecasting potential problems and doing a comprehensive analysis of any on-site impediments, you can create a trouble-free installation.

Start by reviewing past installations. Consider these questions:

- What could you have done better?

- Did your team have the correct training and/or skills to efficiently complete the work requested?

- Was the team communication and role assignments clear on all levels? Each employee should know exactly what, where and how the job will be completed before starting the project.

Then consider the potential issues your team might encounter during the project. Think through the following items:

Sofas and dinettes

- Will your corner dinette or sofa fit through the door?

- The L-shaped construction of a sofa seat and back combo on newer vessels with hydraulic hinge access to sections requires extra time for removal, installation and upholstering.

- Evaluate whether the items should be transported to the shop or completed on-site due to vessel constraints.

- Determine whether any sections are bolted to the floor.

- Decide in advance how you will approach customers if you find hidden damages and what you will charge for repairs.

Carpet/marine flooring

- Know the answer if your customer asks how many snaps or screws you are planning to install into a bulkhead.

- Know the hull thickness prior to drilling/installing new stud screws or snaps for carpeting, especially in a V-berth floor or sidewall.

- Consider transitions and finishing details such as binding around cabinets, sofas, dinettes and steps and any access needed to hatches.

Wallpaper, wall panels and wall surfaces

- Check how many layers of wallpaper are currently on the wall.

- Find an experienced installer, a difficult but essential task. Ensure that the small space, pattern repeat, hardware, transitions and precise cuts are noted ahead of time, as all mistakes will be obvious.

- Review materials with the installer, especially for padded walls, to ensure that the material, glue and wall shape are compatible.

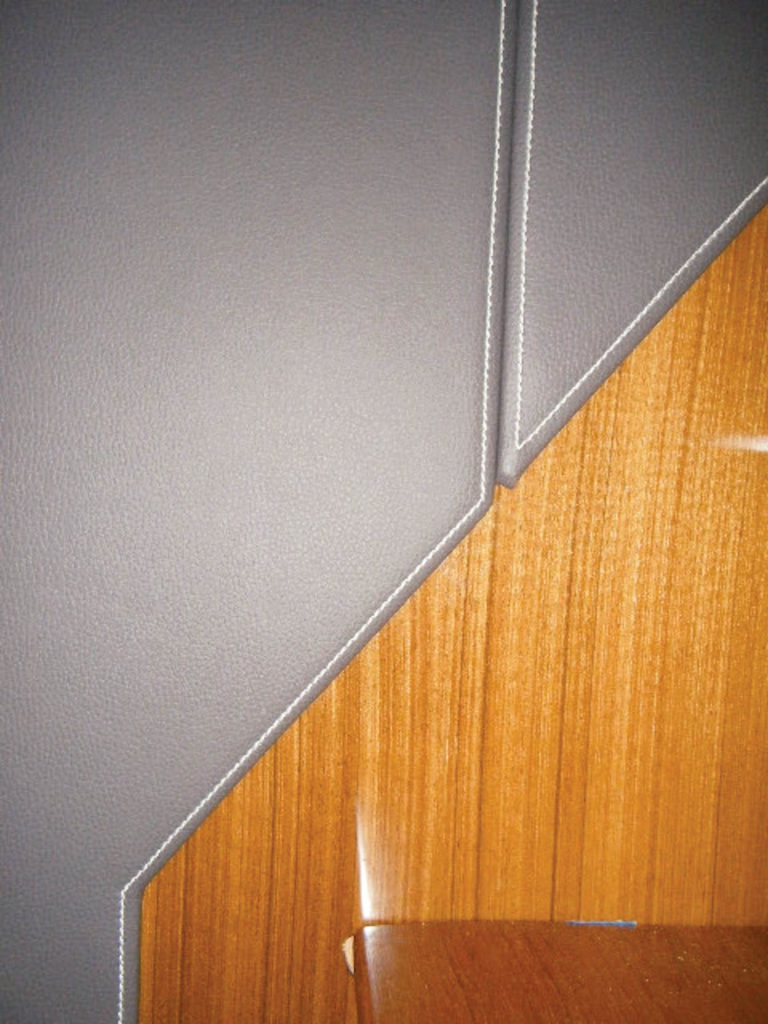

- Decide how you will install wall panels with accent stitching and transitions along steps.

- Understand whether molding or hardware will need to be removed and whether new hardware will be installed.

- Arrange for the air conditioning to be on during the laborious install process in a small space.

Headboards, valances, bedspreads and bed rails

- During the removal of these items, note any damaged or replacement hardware required for the installation. These may become obstacles if you do not include them in your production plan or notify the client.

- Confirm with your customer the additional cost incurred to procure hardware or materials that will upgrade the attachment points in hallways, cabins or bulkheads, such as brackets, hinges, panel fasteners or Velcro.

- Offer materials that will enhance the contours of the cabin space, especially valance panels, as these areas are often unusual shapes with transitions from port and starboard to aft. Review how plaids or geometric patterns will align and look versus linear patterns.

- Consider the additional time and expense for the “little” custom details that clients try to add in at the last minute. You don’t want to be caught saying yes to something that is close to impossible down the road.

Transporting projects to the boat

To allow your team to focus on fabrication and installation (and to prevent your project from falling into the water or your team from getting lost along the way), have professionals transport salon and stateroom items whenever possible.

- Use an experienced, insured and reliable transportation company.

- Keep all transport insurance, license and vehicle information easily accessible to forward to a marina and ensure a timely entry.

- Verify trucks are clean and free of anything that could soil or damage your project.

- Make sure the transportation service asks for permission before moving anything that could be a liability.

- Wrap all goods carefully for transport. Ask clients if they would like the wrappings left in place after installation.

- Confirm that the transportation company and any subcontractors leave all areas clean.

- If you do transport items yourself, make sure all components get into the vehicle. We once traveled more than an hour to a jobsite and then realized the cushion was back at our shop!

Do a postmortem ASAP

Our last piece of advice is to always do a postmortem review with your team immediately after the job is completed. Review what worked, what didn’t work and what you should have done differently. This will keep things fresh in your mind and make these lessons easier to apply to the next project.

Terri Madden (LegendTerri) and Alayna Wool (Ms. Alaynious) are a mother/daughter team who co-own Sand Sea & Air Interiors Inc. in sunny San Juan, Puerto Rico.

www.sandseaair.com

SIDEBAR: Pre-plan and review project timeline steps

- Confirmation of dates the vessel will be accessible

- Agreement and deadlines for priority areas

- How and when items will be removed, transported and installed

SIDEBAR: Establish marina etiquette:

- Anything can fall into the water: protect your tools by tying everything down.

- Let the client know that you need your space. We recommend arranging an agreement that other contractors will not be on board while you and your team are on board. Especially due to COVID-19 restrictions, this is an added layer of safety. Vessel space is usually very tight, and this ensures that a carpenter won’t rest the new cabinets on your client’s new saloon sofa.

- Get a primary and secondary contact from your client. You don’t want to be stuck with your team locked out of the vessel or refused entry to the marina because you are not “on the list.”

- Use a sign-off sheet and have your client approve each stage of the installation to keep everyone in sync.

TEXTILES.ORG

TEXTILES.ORG