Boat interior upholstery techniques

You’ve undoubtedly heard someone say, “Just let the next guys worry about it,” which usually means the product they’re sending out will be nearly impossible for the “next guys” to work on or repair. Boatman Marine Canvas works on all sorts of lake boats that are 38 feet and smaller. Time after time we find ourselves being “the next guys” when we are removing a boat interior for upholstery. Typically, the boat manufacturer has bolted or screwed several of the interior cushions to the upper deck of the boat (the cockpit sole) before attaching it to the boat hull. This leaves us to figure out how to not only remove the cushions, but also how to reattach them using a different method than the original manufacturer.

Over the last 30 years, we have learned a few tricks for getting the job done correctly so “the next guys” won’t have the same problem.

How to find the bolts

Most of the problem areas are the cushion backs in the bow of the boat. First, we examine the boat and remove any bolts we can possibly reach. We are blessed with my 25-year-old son Gavin who is tall and skinny with long arms. We will get him as far into the boat as possible with a flashlight and a wrench to get what he can get (Photo 1). But if you don’t have access to a tall, skinny kid who is not claustrophobic, there is another solution to locating hidden bolts. You can buy an inspection camera that will hook up to your cell phone for less than $20 or an all-inclusive unit for about $100. This will allow you to run a small wire cable into the tightest spaces to spot those pesky bolts you can’t see.

This early 2000s Supra ski boat (Left lead photo) is the perfect example of bow cushions being bolted and wood-screwed before the boat was mounted to the hull. First, you must access these bow cushions from the front side. Get a razor blade and cut off the exterior vinyl cushion cover. Then get a scraper and gently remove the foam from the backer board, which will expose the bolts or screws (Photo 2). Most of the time, the cushions are either bolted or screwed, but rarely both. Supra made doubly sure these bow cushions were not going to fly out of the boat while being towed down the highway, becoming roadkill. The bow cushion backs are bolted and screwed from the back side, making most of the bolts and screws impossible to reach.

*WARNING: Before you start trying to remove the bow cushion bolts, be sure to predrill at least four holes where you will be installing nylon trim retainers. In this case, this is how the new center bow cushion will be refastened to the boat (Photo 3). If you do not drill these holes before you remove the panel, it will be very difficult to get the cushion to line up in the same spot.

Nylon trim fasteners are used primarily in the automotive industry, but over the years we have seen them used in several boats, including 38-foot offshore Cigarette boats, for mounting their side panels. W e buy our trim retainers from a local auto upholstery supplier. They are produced for Auveco Products, product #15479 (Photo 3A). You will need a 9⁄32-inch drill bit to make the mounting hole. Once the 9⁄32-inch holes are drilled, it’s time to start removing the panel.

Removing tough nuts and bolts

After removing the vinyl and the foam, use leverage to get the nut loosened from the backside. Put your scraper or small flat crowbar behind the plastic panel and pry forward while you are loosening the screw with a power drill (Photo 4). This will put the nut on the backside in a bind and will help you get the bolt out. We were able to get all the bolts out except one, which would only come halfway out, so we finally had to use small bolt cutters to cut the bolt head off.

Since the cushions were also screwed in from the backside, we drilled several small holes using a 3⁄16-inch drill bit around the screw tip in a circle (Photo 5). This creates a perforated circle that will allow you to pry the cushion panel off without breaking the plastic board. Now you can remove your cushion and begin your first-class upholstery job.

Access holes help a lot

Of course, we want to reattach as many of the original bolts as possible, and that’s why we decided to cut an access hole in the fiberglass behind the front bow cushion (Photo 6). The access hole, which doesn’t have to be pretty and doesn’t affect the integrity of the boat, allowed us to get to the bolts in the front corners of the bow side panels.

There might be a few situations where you will need to cut an access hole that will be visible from inside the cockpit. When making this strategic cut, purchase an access plate cover and follow the directions on the exact hole size, using the appropriate hole saw blade. This makes for a perfect hole, and the access plate cover will make it look like it came that way from the manufacturer.

Do the diamond jig

This customer wanted to update the interior look, so we kept the same cushion and seat structure but changed the vinyl color, design and added embroidery to a few of the cushions. Dwight Miller, our award-winning interior master craftsman, has created his own diamond jigs. He has two jigs for two different-sized diamonds. The size of the cushions and the overall design determine which diamond pattern we use.

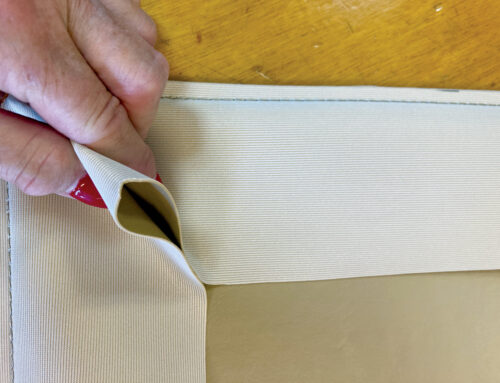

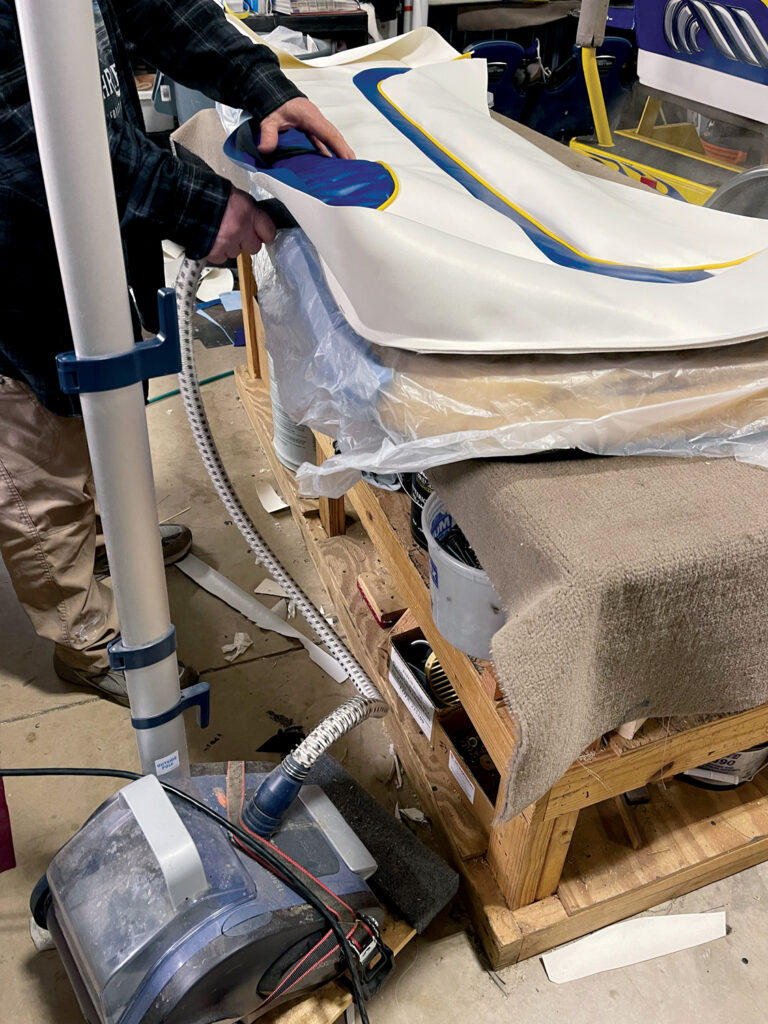

We glue ½-inch stitching foam to the back of the vinyl and trace the diamonds on the foam side of the panel with a Sharpie. This keeps us from having to wipe off diamond marks on the front side of the vinyl. When the vinyl cover is finished, we wrap the foam in plastic and use an apparel heat steamer to get the cover stretched perfectly (Photo 7). After a few stainless steel staples, we are ready to install. Now that you know where all the hidden bolts are and you’ve modified a few bow cushions with nylon trim retainers for easy attaching, reinstalling the cushions is a cinch (Photo 8).

Delight the customer

If we are doing embroidery on a boat interior, something that’s fun for us and really gets a lot of customer appreciation is to embroider two hats and leave them sitting in the boat for customers to discover as they are drooling over their new boat interior (Photo 9). It’s not a hard thing to do, and it’s a nice little surprise that leaves the customer feeling really good.

I hope these tips and tricks will help you when you’re “the next guys or gals” removing the cushions on a boat. Fingers crossed the job will be smooth sailing…or…boating.

Mike Boatman, owner of Boatman Marine Canvas (BMC) in Oklahoma City, Okla., has been working on boats for the last 30 years. His shop specializes in 38-foot and smaller lake boats, re-covering exterior and interior upholstery, custom boat covers and custom bimini tops. In 2023, BMC won the MFA Fabrication Excellence Award of Distinction in Upholstery, and Outstanding Achievement awards in the Travel/Full Covers and Tops and Sunflys categories.

TEXTILES.ORG

TEXTILES.ORG