Adjusting to a bigger shop

In 2019, I moved Chicago Marine Canvas into a new 2,500-square-foot space, and by the summer of 2021, customer projects were piling up on top of one another. An additional sewing table had been made under a low storage loft, we were constantly moving projects in the middle of production to complete everyday tasks, and too many avoidable mistakes were happening. It was time to start searching for a larger space!

After seven years in business, we had become a full-service shop of seven employees helping boaters with their canvas and upholstery needs as well as other projects such as shade sails, industrial covers and even Boeing 777 jumbo jet engine and landing gear covers.

Eventually, I found an old 7,500-square-foot warehouse space that needed an extreme makeover, and the renovation began. The most challenging hurdles to overcome though could not be solved with a trip to Home Depot.

Customer and project organization

As project volume, employee headcount and the scope of the business increased, I knew the current paper filing system would no longer work. I’d implemented an inexpensive customer relationship management (CRM) system, and its limitations meant workflow was still not fluid.

I moved to Salesforce and have since gone all in and embedded it into our day-to-day activities. My employees have all been trained to enter new customer information into the CRM tool. Boats, customer names and projects are all linked together to assist in project status, current production stage and billing. Employees are also able to update project status when their production stage has been completed. Custom reporting can be generated by various metrics including project type, materials used, production stage and boat specifics such as make, model and location. We saw the benefits immediately through a better customer experience and greater employee awareness of the project pipeline.

Although the Salesforce CRM tool did involve some customization, which was all done in-house, the integration has been a success. Our future integration plans are to link the CRM tool to the current accounting software and company website customer intake form, automating even more of the day-to-day administration.

Communication challenges

Employee communication is the cornerstone of a company’s success and once we moved to our new location, the communication challenges were immediately evident. We are now spread out over three floors: the customer showroom, carpentry department and upholstery department are on the first floor; cutting, large project sewing, embroidery, specialty machines and our break room are on the second floor; and our primary sewing area is on the third floor.

Initially, there were too many trips up and down the stairs for basic questions, employees weren’t helping each other due to physical location constraints, and there was a lack of skills knowledge and mentoring happening. So, our team came up with some easy solutions:

- “Alexa, how do I pattern a boat cover?” I purchased video-enabled Amazon Echo Show devices and spread them out across the shop. Employees can now easily communicate with each other through video calls, saving valuable time. While off-site at boatyards and harbors, installers can even use their phones to video chat with the shop to see installation processes live and get answers to any fitting questions. The devices connect to the shop’s Wi-Fi and don’t require a monthly subscription cost. Employees can even stream their own music over the speaker!

- Weekly team meetings. Our team reviews production reports by project type, which allows everyone to understand the different types of work being done. Employees can bounce ideas back and forth, and discuss and prepare for upcoming projects, deadlines and past project successes.

- Cross-training/mentoring. Custom fabrication work is unique, as every project is different and is a daily learning experience. All sewers at Chicago Marine Canvas come from a production work background and they like the challenge of new projects in our line of work. My employees have their individual areas of expertise, but they also assist others outside of it. It could be a canvas sewer helping with an upholstery project, the upholsterer assisting with an install, or an installer getting behind a sewing machine. This has helped with cross-skill education, with employee engagement and in filling gaps during vacations.

At Chicago Marine Canvas, we are still settling in and finding new ways to improve our processes. To help in this journey, we have taken advice from another MFA member and have hired our first college intern for the summer. So far so good!

Vince Innocenzi is the owner of Chicago Marine Canvas, which services the Chicago, Ill., area for custom marine-related canvas and upholstery products. His company has been in business for seven years and is a team of seven fabricators.

SIDEBAR: Shop process adjustments

Here’s a short list of some of the changes and adjustments in the sewing, upholstery and installation areas of our shop that we have put in place since moving into our new location.

- Mobile air filtration system. The importance of fresh/clean air cannot be overstated. Due to the age of our new location’s building, it was difficult to add ductwork to areas of the shop to vent fumes from spraying glue, using hot knives and carrying out other manufacturing processes. A mobile industrial air cleaner was the right solution for this problem. It can be moved around the shop depending on where it’s needed and has the compacity to cycle all the air in a 2,000-square-foot room in five minutes!

- Sewing tables. Space was always a constraint in past locations but it’s plentiful now. Our new primary sewing table on the third floor is a rectangle that is 36 feet long by 15 feet wide. It fills the space of the six steel support posts that run through each floor. There are three stations with Juki DNU-1541S lockstitch sewing machines and the fourth is for a Juki MO-6816S overlocker.

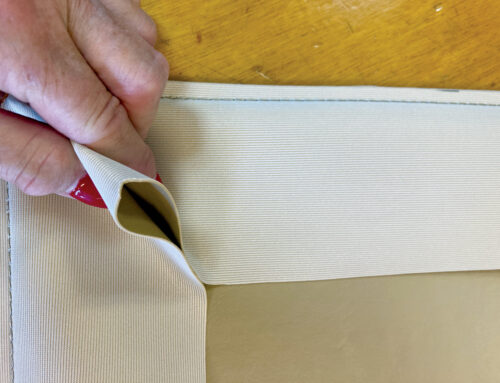

- At our shop, we overlock stitch raw edges rather than hot knife the fabric, and by having an overlocker on the same table as the primary sewing machines, we can easily pass the fabric between the two machines. We have a similar table alignment on the second floor, but with a Durkopp Adler Long Arm and Juki Double Needle LU-1560N sewing machine. We added smaller 10-by-6-foot layout tables for preparing and organizing work that needs to be completed or for finished products ready for installation.

- Mobile carts. An ongoing challenge has been transporting completed projects from the sewing room to the customer’s boat. This task is now even more challenging because the sewing room is on the third floor with access via stairs or an old freight elevator. We came up with a simple solution: laundry and hotel valet carts. The laundry carts are perfect for transporting cockpit covers, travel covers and bimini tops, and the valet carts are used to hang enclosure panels. The carts transport the goods to the freight elevator, keeping them protected, and then the carts are loaded directly into our work truck. The carts are unloaded at boatyards or marinas and are rolled right to the boat for unloading. This process better protects customer projects during transport and also speeds up the installation process.

TEXTILES.ORG

TEXTILES.ORG